Application Of Glazed Tile Roof Sheet Roll Forming Machine

The glazed tile roof sheet roll forming machine is an impressive piece of equipment known for its high precision and rapid operation. It efficiently converts raw materials into attractive glazed tile roof sheets in no time.

With its rollers synchronized perfectly with the conveyor system, materials pass through smoothly, gradually taking shape and form. This machine not only minimizes labor requirements but also ensures consistently high-quality roof sheets.

In addition, the machine is easy to adjust and maintain, making it a popular choice among roofing product manufacturers.

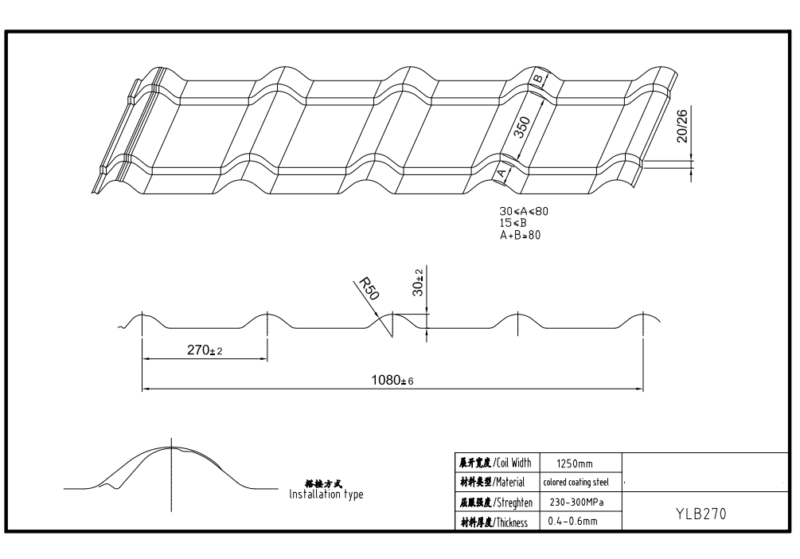

The Drawing Profile:

Finished product picture:

Glazed Tile Roof Sheet Roll Forming Machine Working Flow:

The Main Technical Parameter Of Glazed Tile Roof Sheet Roll Forming Machine:

|

Glazed Tile Roof Sheet Roll Forming Machine |

|||

| Series | Details | Parameter | Comment |

| Material | Raw material | Steel | Customer confirmed |

| Material thickness | 0.4-0.6 mm | ||

| Decoiler | Structure | Manual passive type | The standard one to match the production line |

| Single head type | |||

| Loading capacity | 1.5 Tons | ||

| Coil inner diameter | 450-550 mm | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 45# STEEL with tempering | ||

| Shaft diameter | 50 mm | ||

| Roller material | GB-Cr12 | ||

| Rolling station | 21+1 stations | ||

| Work speed | About 7-9m/min | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Steel plate welded | ||

| Bearing | Roller bearing | Famous brand of Harbin | |

| Total Power | 21.55KW | ||

| Transmission | By gear | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new! | |

| Decoiler, we can change to hydraulic one if you need. | |||

| PLC control system | 1.Operation: screen+ button

2.MITSUBISH, Frequency |

||

| Hydraulic station | Famous Chinese brand | ||

More pictures of the machine:

-

Pre-Cutting Device

This component is designed for the initial cutting of the sheet before it enters the main processing system.

-

Guiding Device

The guiding system uses a guiding bar and sliding block to control the positioning and width of the steel sheet. This ensures the sheet is properly aligned and directed into the roll forming equipment for further processing.

-

Roll Forming System

– Machine Frame: Constructed using a welded structure that undergoes blasting treatment for durability.

– Rollers: Made from high-quality No. 45 steel and coated with hard chrome for increased longevity and wear resistance.

– Roller Support Structure: Features a guiding column for improved stability and alignment.

– Drive Mechanism: The system is powered by a servo motor, with the back and forward rollers driven by a chain mechanism, while part of the upper and lower rollers are driven by gears.

– Roller Adjustment: A manual screw adjustment is used to set the distance between the upper and lower rollers, allowing for the accommodation of different sheet thicknesses

-

Punching Die and Cutting Device

– Cutting Blade: Made from Cr12 steel with a quenched treatment, ensuring minimal material waste during the cutting process.

– Power Supply: The cutting function is powered by a hydraulic station.

– Punching Depth Options: The punching die offers two depths for tile profiles: 20 mm and 26 mm. When changing the gaskets, the lower die can be easily replaced using a cylinder lifting mechanism for convenient maintenance.

This revised version maintains the original meaning but adjusts the sentence structures and word choices for better clarity and flow.

Light Gauge Steel Framing Machine Specification Width(web): 89mm Height(flange): 41mm Lip:7-12mm The machine match with 3 sets […]

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

STAY IN THE LOOP