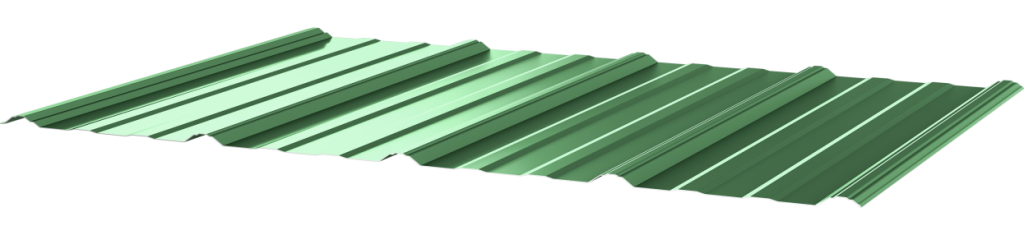

Trapezoid roof panel roll forming machine,High Quality Master Rib Trapezoid Roof Panel Roll Forming Machine

MasterRib of Specifications

- Applications: Roofing Panel, Wall Panel

- Fastener: Exposed Fastener

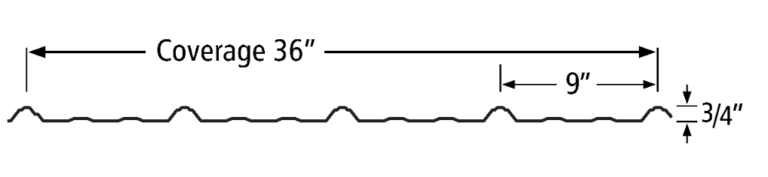

- Coverage: 36″ Coverage

- Rib Height: 3/4″

- Minimum Recommended Slope: 3:12

- Suitable for solid deck or open framing

The MasterRib metal roofing panel is renowned for its robustness and durability. This highly versatile panel, which boasts a classic appearance, is used across various applications including residential, commercial, and post-frame structures. Designed with wider ribs, it enhances both strength and ease of installation. Additionally, the panel features a large siphoning channel on the under-lap rib, offering superior leak prevention even under severe wind and rain conditions.

Substrates and Coatings

- High Strength Steel Gauge Options: 26 GA, 29 GA

- Finishes: Painted Panels, Unpainted Panels

- Anti-corrosion AZ50 Galvalume coating for painted and AZ55 for unpainted steel

- 45 Year and Signature 200 Paint System

Profile drawing:

The technical specifications of the Trapezoid roof panel roll forming machine:

| em | Name | Specifications |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.3-0.5mm |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| 4 | Roller station | 18 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by chain |

| 9 | Motor power | 5.5kw moter |

| 10 | Machine frame | 350H steel welded |

| 11 | Cutting type | Hydraulic cutting |

| 12 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 with quenched treatment |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | PLC |

| 17 | Brand | PLC:Delta/Siemens/MitsubishiTouch screen:Delta/Siemens/MitsubishiEncoder:Omron |

Feeding Device

1.Hand wheels on both sides can be used to adjust the feeding width. 2.Four stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface. 3.There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

Roll Forming And Transmission Device

1.rollers thick chromed good hardness for long service time. 2. Each roller has number and with keynotes, it can fix on the shaft stablely 3.gear and double chain,stable

Hydraulic Cutting Device

We use four pillars cutting system structure, it can make sure the cutting stable

PLC control system

PLC brand:Delta(Taiwan) PLC, and transducer and touched screen ● Encoder brand:Omron ● Electrical components:Schneider ●Operating language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Hydraulic station

● Hydraulic station motor:5.5KW ● Hydraulic oil:46# hydraulic oil ● Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Cangzhou Zhongtuo Cold Roll Forming Equipment Co., Ltd. is proud to announce the successful commissioning […]

Dec. 12th 2024 Russian customers came to visit the standing seam machine, decoiler machine, ridge cap machine. […]

STAY IN THE LOOP