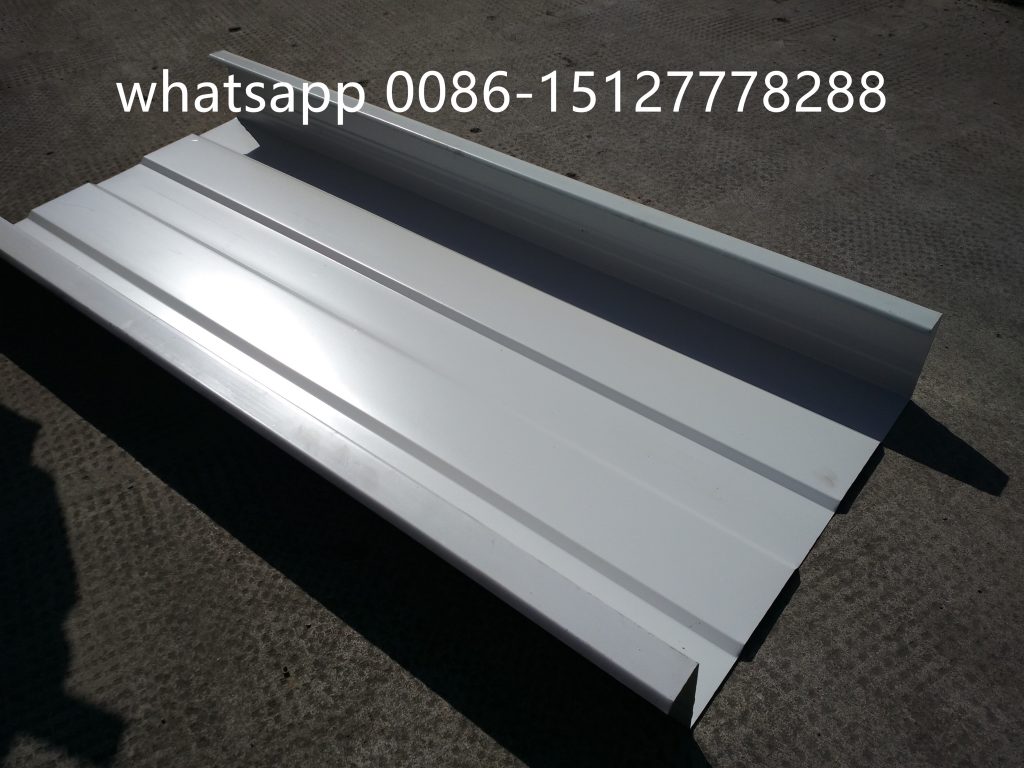

High Quality Snap Lock Roof Panel Roll Forming Machine,interlocking mechanisms

Snap Lock Roll forming Machine Description:

A snap lock roll forming machine is a specialized piece of industrial equipment designed to produce snap lock profiles in a continuous manner from metal coils or other materials. These profiles, widely used in the construction sector for roofing and wall cladding, feature interlocking mechanisms that enable them to securely snap together, ensuring a weather-tight seal.

The roll forming process involves feeding a metal coil through a sequence of rollers. Each roller set incrementally shapes the material into the required profile. For snap lock profiles, the machine creates both the male and female interlocking components as the material moves through the rollers. This results in a long, uninterrupted length of material with the snap lock design..

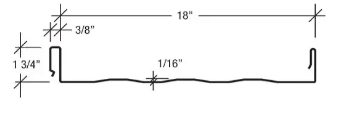

drawing:

Options

- Extra Spools

- Hydraulic Shear

- Cut-to-Length controller

- 50 Cycle Wiring

- 220 Volt Wiring

- Overseas Wiring

Key features of a snap lock roll forming machine may include:

- Rollers: These are precision-engineered to create the specific snap lock profile accurately and consistently.

- Feeding Device: The machine typically includes a decoiler to hold the metal coil, a leveling system to ensure flatness, and a feeding mechanism to advance the material through the rollers.

- Hydraulic Cutting Device: A snap lock roll forming machine may have a flying cutoff or stationary shear to cut the formed profile into the desired lengths.

- PLC Control System: Modern roll forming machines are often equipped with computerized control systems for precise adjustment of roller positions and machine parameters.

- Tooling: The machine may require different sets of tooling (rolls) to produce various snap lock profiles.

The technical specifications of the Snap Lock Machine roof panel roll forming machine:

| em | Name | Specifications |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.3-0.5mm |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| 4 | Roller station | 18 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by chain |

| 9 | Motor power | 5.5kw moter |

| 10 | Machine frame | 350H steel welded |

| 11 | Cutting type | Hydraulic cutting |

| 12 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 with quenched treatment |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | PLC |

| 17 | Brand | PLC:Delta/Siemens/MitsubishiTouch screen:Delta/Siemens/MitsubishiEncoder:Omron |

The ZTRFM NLT350 digital intelligent purlin machine represents a new era of digital manufacturing. It […]

Light Gauge Steel Framing Machine Specification Width(web): 89mm Height(flange): 41mm Lip:7-12mm The machine match with 3 sets […]

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

STAY IN THE LOOP