Board and Batten Roll Forming Machine, it is designed to create the profile required for board and batten siding.

A Board and Batten Roll Forming Machine is an industrial tool utilized in the construction sector to manufacture board and batten siding. This siding style, favored for its traditional and rustic look, features broad vertical panels (the “boards”) with narrower vertical strips (the “battens”) placed over the seams between the panels. This type of siding is widely chosen for exterior cladding on buildings due to its distinctive appearance.

The Board and Batten rollformer has many features including:

- 30 to 26 gauge capacity

- Variable speed control

- Compact footprint at 34 inches wide

- Optional Striations or flats

- Air cylinders to engage or disengage striation pass

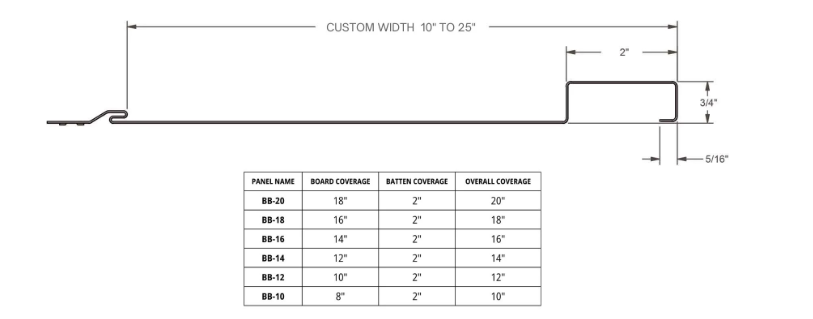

Profile drawing:

Key features of a snap lock roll forming machine may include:

- Rollers: Typically, the machine starts with a roll of flat metal sheet or coil, which can be made from materials like steel, aluminum, or other metals used for siding.

- Feeding Device: The metal sheet or coil is fed through a series of rollers that are specially designed to gradually bend and shape the material into the desired board and batten profile. This process may involve multiple stations or sets of rollers to create the various features of the siding, including the wide boards and narrow battens.

- Hydraulic Cutting Device: At certain points along the roll forming process, the machine may have a cutting mechanism to trim the sheet to the desired length and create individual siding panels.

- PLC Control System: Modern roll forming machines are often equipped with computerized control systems for precise adjustment of roller positions and machine parameters.

- Stacking or Packaging: Once the siding panels are formed and cut, they are usually stacked or packaged for easy transportation and installation..

The roll forming process is a method of shaping metal sheets or coils into specific profiles by passing them through a series of rollers. In the case of a Board and Batten Roll Forming Machine, it is designed to create the profile required for board and batten siding.

Board and Batten Roll Forming Machines design philosophy

Board and Batten Roll Forming Machines come in various sizes and configurations to accommodate different materials and production needs. Some machines may be fully automated, while others require manual adjustments and operation. They are an efficient way to mass-produce board and batten siding with consistent quality and precision.

Board and batten siding is a timeless design choice that can add character and charm to residential and commercial buildings. Roll forming machines, like the Board and Batten Roll Forming Machine, play a crucial role in manufacturing this type of siding efficiently and cost-effectively.

The technical specifications of the Board & Batten roof panel roll forming machine:

| em | Name | Specifications |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.3-0.5mm |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| 4 | Roller station | 18 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by chain |

| 9 | Motor power | 5.5kw moter |

| 10 | Machine frame | 350H steel welded |

| 11 | Cutting type | Hydraulic cutting |

| 12 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 with quenched treatment |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | PLC |

| 17 | Brand | PLC:Delta/Siemens/MitsubishiTouch screen:Delta/Siemens/MitsubishiEncoder:Omron |

April 15, 2025 Booth 20.1H01-02 | April 15–19, 2025 | Guangzhou, China [Guangzhou, China] — […]

The ZTRFM NLT350 digital intelligent purlin machine represents a new era of digital manufacturing. It […]

Light Gauge Steel Framing Machine Specification Width(web): 89mm Height(flange): 41mm Lip:7-12mm The machine match with 3 sets […]

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

STAY IN THE LOOP