Description of Furring Channel Forming Machine

A Hat Channel Roll Forming Machine is an industrial device used to produce hat channels, which are widely utilized in construction and various other industries. These channels have a shape resembling the letter “U” or a hat, giving them their name, and serve as structural supports or framing elements in applications such as walls, ceilings, and roofing systems.

The roll forming process works by feeding a continuous metal strip (typically steel or other metals) through multiple rollers and dies that gradually shape the material into the required profile. For hat channels, the machine is specifically engineered to bend the metal strip, forming a cross-section in the shape of a “U” or hat.

Hat Channel Roll Forming Machine Specification

- Weight: 2500lbs

- Profile: 1″ x 2″ x 1″ – 1/2″deep

- 40ft per minute

- Machine size: 18ft x 3 x 5ft

- Power: electric 240v three phase 60 Hz

- materials:

- Speed:

- Electric shear

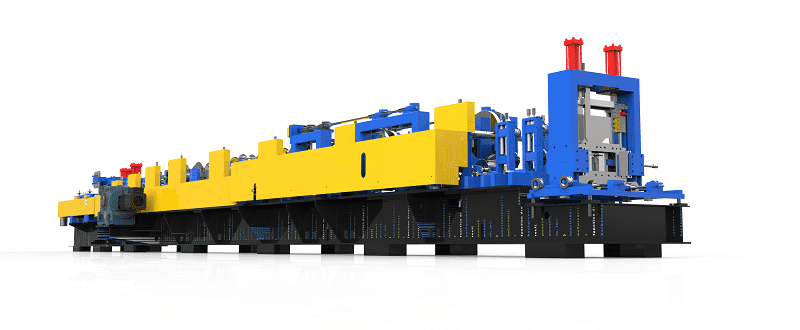

Here are the key features and components of a Hat Channel Roll Forming Machine:

Entry and Feeding System: The machine typically includes a mechanism that allows the metal strip to be loaded and fed smoothly into the roll forming section.

Roll Forming Stations: These stations form the core of the machine and consist of multiple rollers and dies arranged in sequence. Each station gradually shapes the metal strip, with each one performing a specific operation. For hat channels, the stations bend the strip progressively to achieve the required profile.

Cutting Mechanism: Once the metal has been shaped into a hat channel, a cutting mechanism is often integrated to cut the formed channel to the desired length.

Control System: Most modern roll forming machines are equipped with computerized control systems that let operators set parameters such as the hat channel’s dimensions, the speed of production, and other settings.

Material Handling and Output: After production, the completed hat channels are typically transported out of the machine via a conveyor or material handling system for further processing or packaging.

Hat Channel Roll Forming Machines are widely used in industries such as construction, automotive, and manufacturing, where hat channels are used as framing or structural components. These machines offer consistent dimensions and high production efficiency, making them essential to many production processes. The machine’s design and specific capabilities vary based on the manufacturer and application needs.

Hat Channel Profile: A hat channel profile, also referred to simply as a “hat channel,” is a metal framing or support component used in construction and various industrial applications. Its name comes from its distinctive shape, which resembles a “U” or a hat when viewed in cross-section.

Profile drawing:

The technical specifications of the Metal Stud Furring Channel Forming Machine:

| ZTRFM light gauge steel gauge metal stud and track roll forming machine | ||

| 1.Formed Material | PPGI,GI | Thickness:0.4-1.2mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 14 rows(As your requirement) |

| Diameter of shaft | 60 mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | Gear transmission | |

| Dimension(L*W*H) | 7800*800*1200(customize) | |

| Weight | About 4.5T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW*2 sets |

| Hydraulic system power | 5.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 0-40m/min(customized) | Different speed designs for options. |

More pictures of the machine:

Light Gauge Steel Framing Machine Specification Width(web): 89mm Height(flange): 41mm Lip:7-12mm The machine match with 3 sets punching die(75~96/138-159/180-200)mm […]

Cable Tray Machine Profile Drawing: CABLE TRAY MACHINE INFO. OF STEEL MATERIAL: Ø Raw material request: […]

2” Composite Metal Decking Roll Forming Machine Profile: 2″ Composite Profile size: 2″ Forming Speed: […]

Specializations Steel framing machines for wall panels, trusses, and floor joists in residential and commercial […]

STAY IN THE LOOP