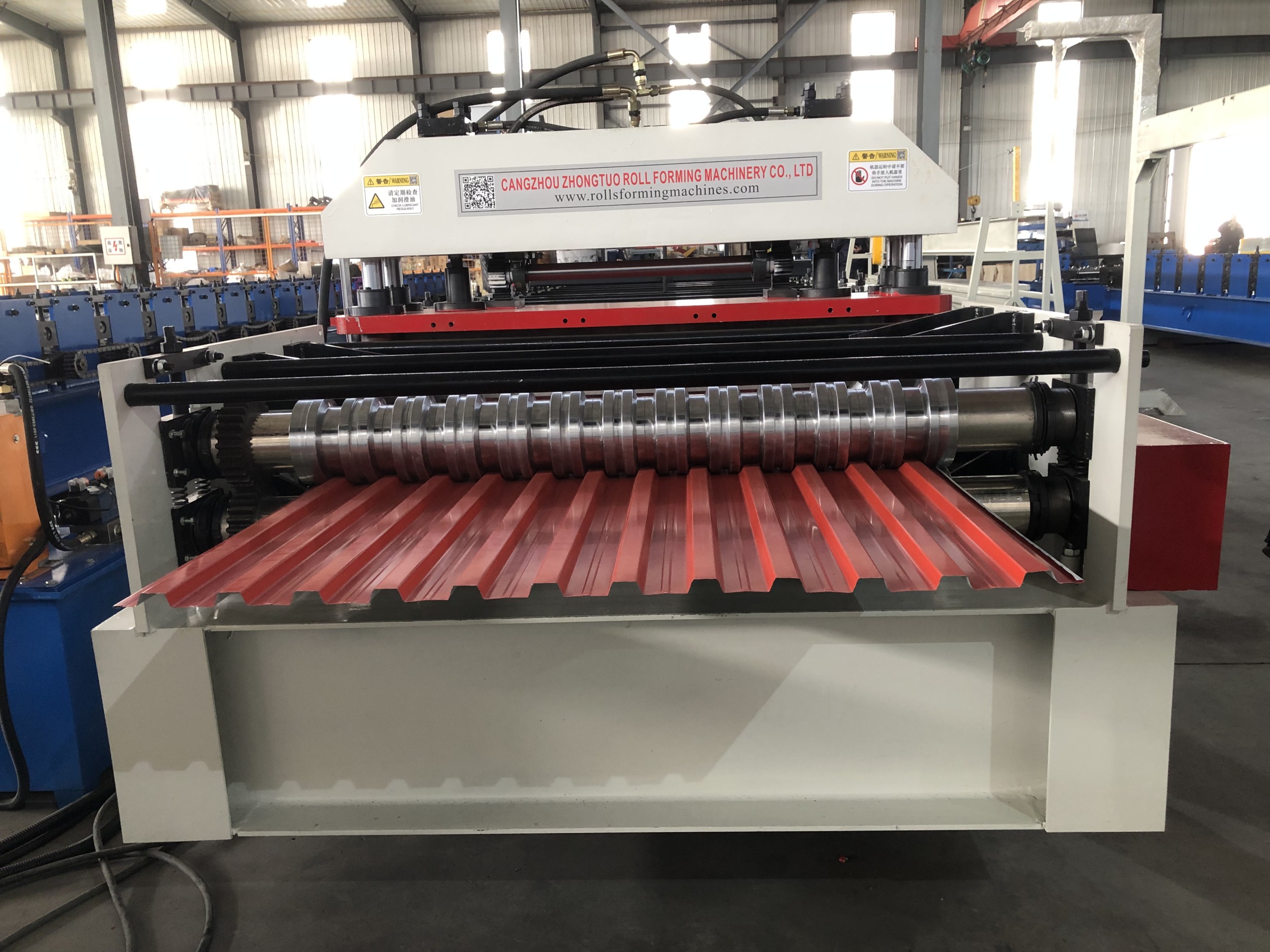

Bar Steel Roll Forming Machine

ZTRFM Automation Remote Monitoring Galvanized Steel Type z bar steel roll forming machine is a single roll forming unit that can produce various specifications of Z-shaped purlin products by rolling. The machine mainly consists of Manual decoiler, leveling devices, punching devices, Roll forming machine, hydraulic stations, PLC control systems, etc. This machine adopts automatic punching and is easy to operate.

Description of Z Bar Steel Rolling Forming Machine

Compact, fixed, cassette-equipped, and width-adjustable duplex roll forming machines are available in multi-profile and combined configurations, designed for producing various types of profiles, including open, closed, and special profiles. These lines are specifically engineered for sheet metal processing. Profiling lines can be seamlessly integrated with manipulators and servo-controlled Cartesian robots, facilitating operations such as stacking, palletizing, and packaging.

Materials compatible with the machines include galvanized steel, pre-painted steel, stainless steel, and aluminum. Each machine is fully customizable to meet the user’s specific requirements and is designed with Industry 4.0 interconnection capabilities.

Z Bar Steel Roll Forming Machine Specification

- Power: 22 kW-30 kW (3 phases, 50 Hz, 380 V)

- Weight: 20 -25 tons (according to profile)

- Dimensions: L = 17-22m ; W = 1.8m ; H = 1.9m

- Number of pairs: 32 -42

- Forrming speed: 16 -18 mpm

Z Bar Steel rolling forming machine working flow:

The Technical Specifications Of The Z Bar Steel Rolling Forming Machine:

| Z Bar Steel rolling forming machine | ||

| 1.Formed Material | GI | Thickness: 0.3-2.0mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 14 rows(As your requirement) |

| Diameter of shaft | 50mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | Gearbox transmission | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Weight | About 3T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW |

| Hydraulic system power | 5.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 70m/min(customized) | Speed is adjustable according to customer’s request |

More pictures of the machine:

Producing Shelf Storage P-Beam Roll Forming Machine Material Material Thickness: 0.6-1.5mm Applicable material:Galvanized Steel(GI),Cold Roll Steel(CRC) […]

What is a L purlin used for? L-shaped purlin plates serve as beams that support the […]

Description of M Purlin Roll Forming Machine ZTRFM’s unique ‘M’ shape purlin is designed with greater torsional […]

The Australia-style roller shutter door roll forming machine, when paired with a 6-meter electric seaming […]

STAY IN THE LOOP