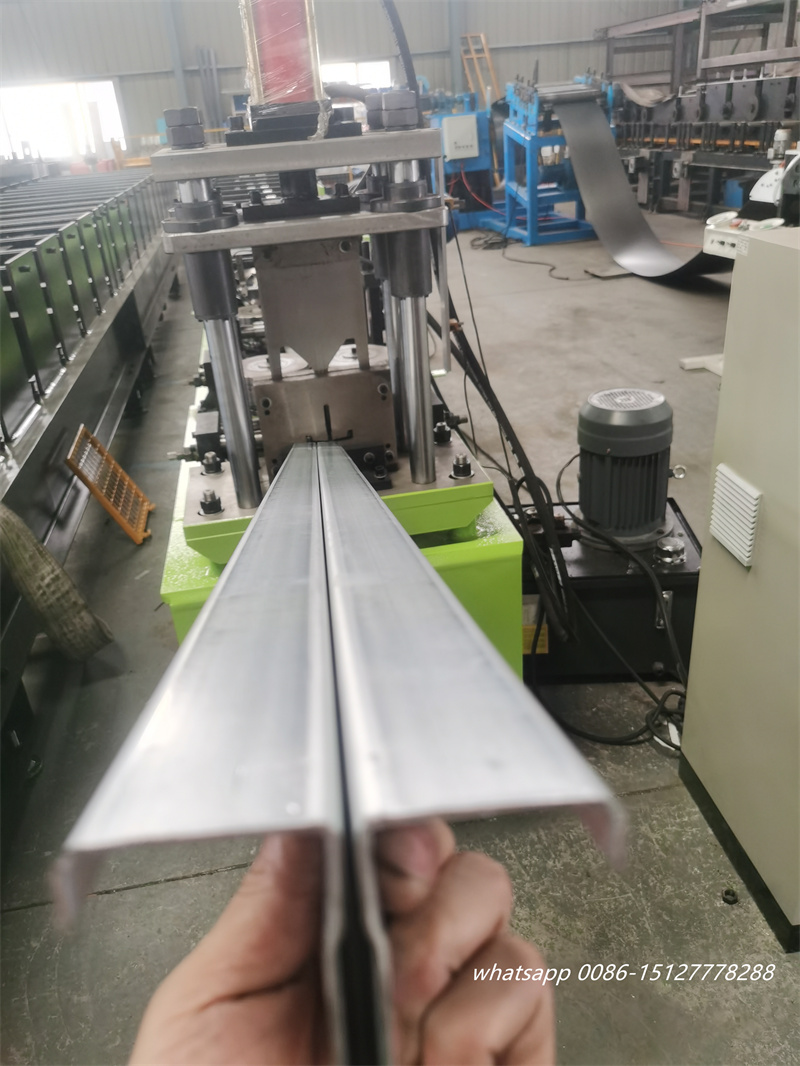

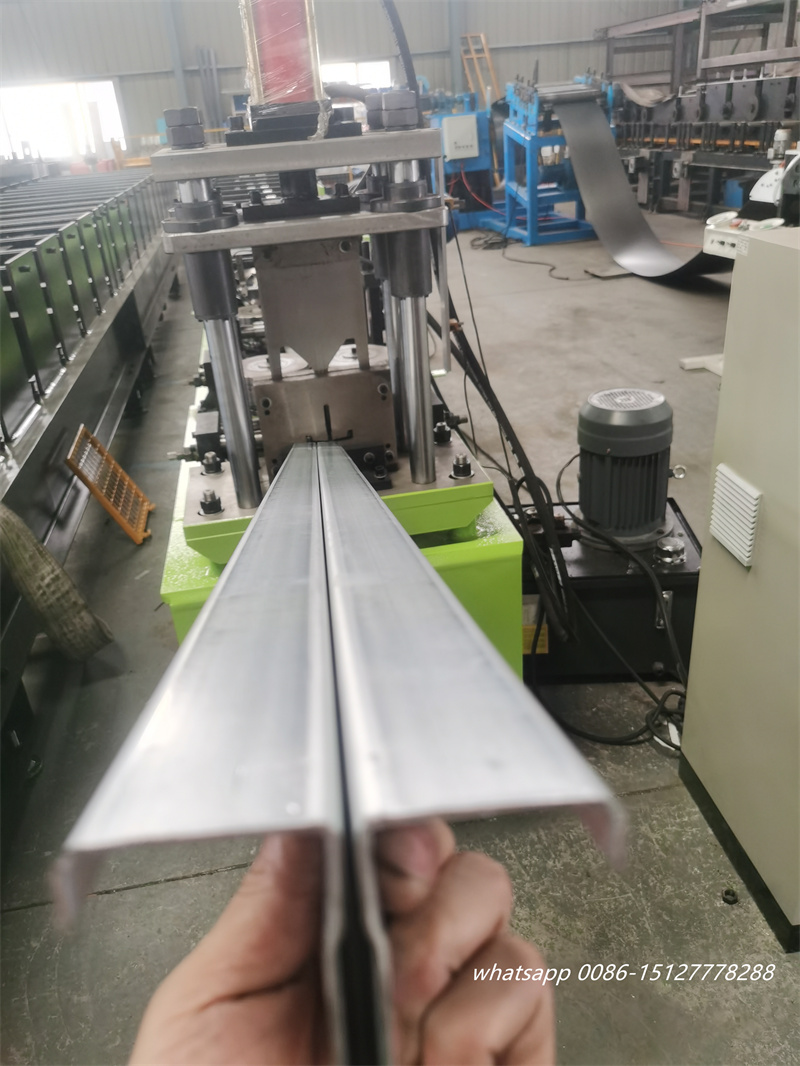

Specifications for Sheet, Zinc-Coated, (Galvanized) WindBrace Steel Roll Forming Machine by the Hot-Dip Process.

- Galvanized G60 to ASTM A653

- Mechanical properties to ASTM A653

- Panel Design thickness of 5mm

- Begin by establishing a run-line using the bracing as a guide for a straight edge.

- Make a single saw kerf cut at least 1/2” deep along the run-line.

- Insert the bracing web into the kerf and secure it by nailing it to the studs.

- For walls pre-framed on the floor, position the bracing web into the kerf and drive a nail into the top plate.

- Lift the wall into position and ensure it is plumb before securing the top plate, bottom plate, and studs according to the nailing schedule.

Windbrace is designed to offer resistance against racking during the construction process and also allows for exterior insulation. It has a flat surface which makes it easy to use both inside and outside.

Main machine parameters:

Voltage: As customer request

Material thickness: 1.5-3.0 mm, yield strength≤G345Mpa

Processing material: PPGI,GI, Q345, HR steel etc.

Working speed: 0-12 m/minute

Profile drawing:

WindBrace Steel Roll Forming Machine working flow:

The Technical Specifications Of The Wind Brace Steel Roll Forming Machine:

| Wind Brace Steel Roll Forming Machine | ||

| 1.Material of coil | Material Thickness | 1.5-3.0 mm |

| 2.Forming system | Rolling Speed | 0-12m/min( without the cutting time) |

| 3.Main body

|

Roller Stations | About 20 stations |

| Roller Material | Cr15 | |

| Maim Motor Power | 15 kw | |

| Hydraulic cutting Power | 2.2 kw | |

| Leveling rollers | 4 up + 5 down | |

| Material Of Cutting | CR12 with quench treatment | |

| yield strength | ≤G345Mpa | |

| Tolerance | +-1.5mm | |

| 4.Cutter | Cutting way | Stop cutting |

| 5.Voltage | Electric Source | Also can satisfy Customer’s require |

| 6.Control system | Control System | PLC Delta |

| Inverter | Yaskawa | |

| Weight | About 2.5 tons | |

| Table size | 3.0 x 1.0 x 0.9m | |

| MOTOR | Under the frame of the machine | |

More pictures of the machine:

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP