Features and Advantages of the Solar Photovoltaic Support Rolling Machine

– The machine is capable of roll forming for both light-duty and heavy-duty applications, offering versatility across different production needs.

– Interchangeable spacers are included, enabling the production of profiles in a variety of sizes to meet specific project requirements.

– It is equipped with an inline flexible punching system, enhancing operational efficiency and reducing processing time.

– Options for both pre-cutting and post-cutting are available, offering flexibility in the production process.

– The machine operates at speeds ranging from 12 to 15 meters per minute, ensuring high throughput.

– It complies with European quality standards and holds multiple patents, including CE certification, ensuring reliability and safety.

– Machines are readily available in stock, ensuring quick delivery for customer orders.

Suitable Coil Materials for the Solar Panel Rack Forming Machine

– The machine can process various materials, including cold and hot-rolled steel, as well as galvanized steel.

– Material thickness ranges from 1.5 mm to 3.0 mm, accommodating different structural needs.

– The yield strength of the materials processed is within the range of 230 to 300 MPa.

– The width of the material is customizable based on the specific profile requirements of the project.

Quality Assurance

ZTRFM ensures that every solar bracket roll forming line is designed according to the client’s specific requirements. All machines are brand new, built according to the provided specifications and performance expectations, ensuring smooth and trouble-free operation.

Advantages of the Solar Bracket Roll Forming Machine

This production line is designed to manufacture high-quality solar PV supports efficiently. The machine offers several key advantages:

– A user-friendly PLC control system for automated operation, simplifying the production process.

– Gcr15 rollers that have undergone a quenching treatment to achieve a hardness of HRC 60-65, ensuring long-lasting performance.

– A tracking cutting system equipped with Cr12 cutting blades, offering precision and durability.

Solar mounting bracket Drawing:

Applications of Photovoltaic Brackets

Photovoltaic brackets are increasingly favored due to their eco-friendly, durable, and cost-effective nature. Made from materials like double-in-roll C-shaped steel and other robust construction steels, these brackets provide easy and quick installation and maintain an aesthetically pleasing appearance. They are versatile and suitable for numerous applications, including:

– Light steel structure construction

– Shelving systems

– Ceiling frameworks

– Various other structural support functions

These brackets are designed to allow the adjustment of solar panels at different angles, optimizing the capture of local solar energy and maximizing the energy output of solar modules. The connection methods, material selections, and load capabilities are rigorously assessed, improving the physical performance of the modules. This includes enhancing their resistance to environmental factors such as earthquakes, wind, snow loads, and corrosion, ensuring their suitability for diverse applications and environments.

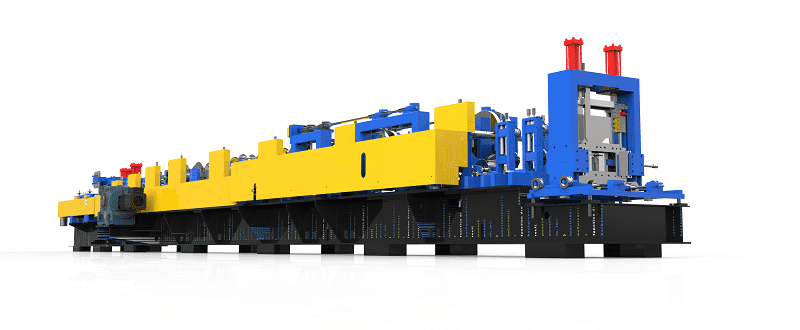

Strut Channel Roll Forming Machine Working Flow:

The Technical Specifications Of the strut channel Roll Forming Machine :

|

Strut Channel Forming Machine |

|||

| Series | Details | Parameter | Comment |

| Material | Raw material | Galvanized steel | Customer confirmed |

| Material thickness | 1-2 mm | ||

| Decoiler | Roller station | 9 rollers | The standard one to match the production line |

| upper 3 + down 4 to level the coil | |||

| Loading capacity | 3 Ton | ||

| Coil inner diameter | 450-550 mm | ||

| 80 Ton punching machine & punching dies

|

Power: | 80 tons mechanical press power | |

| 15 holes punching mold | |||

| Speeds: | 45 times /min, 8-10 m/min | ||

| Include punching mold: | mold material SKD-11 | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 40 Cr with tempering treatment | ||

| Shaft diameter | 80 mm | ||

| Roller material | Gcr15, some are Cr12 HRC 56-58 | ||

| Rolling station | 18 stations | ||

| Work speed | 45 times /min, 8-10 m/min | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Cast iron mold frame (very strong frame) | ||

| Bearing | Chinese famous brand Harbin | Famous brand of Harbin | |

| Work power | 5.5kw*2, 7.5kw*2 | ||

| Transmission | Gear box transmission | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new!

|

|

| Decoiler, we can change to hydraulic one if you need. | |||

More detailed pictures of the machine:

Light Gauge Steel Framing Machine Specification Width(web): 89mm Height(flange): 41mm Lip:7-12mm The machine match with 3 sets punching die(75~96/138-159/180-200)mm […]

Cable Tray Machine Profile Drawing: CABLE TRAY MACHINE INFO. OF STEEL MATERIAL: Ø Raw material request: […]

2” Composite Metal Decking Roll Forming Machine Profile: 2″ Composite Profile size: 2″ Forming Speed: […]

Specializations Steel framing machines for wall panels, trusses, and floor joists in residential and commercial […]

STAY IN THE LOOP