The Australia-style roller shutter door roll forming machine, when paired with a 6-meter electric seaming machine, is designed to manufacture robust and secure shutter doors. These doors are renowned for their durability and safety features, effectively addressing concerns such as burglary, fire, and other potential issues. The production process involves the roll forming machine shaping the shutter door panels, which are then seamlessly joined by the electric seaming machine, ensuring a strong and reliable final product.

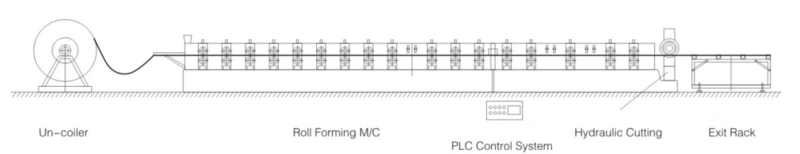

Work flow Overview

The manufacturing process begins with a 5-ton decoiler that feeds and guides the metal panels into the main roll forming machine. This machine operates under the control of a PLC (Programmable Logic Controller) system, which ensures precise and consistent production. Following the formation of the shutter door, a hydraulic cutting device trims the material to the desired length. Finally, the finished products are collected on a receiving table.

Key Features

– Cost-Effective: Offers excellent value for money.

– High Efficiency: Produces up to 12 meters per minute, maximizing productivity.

– Reliability: Ensures dependable operation over long periods.

– Energy Efficient: Minimizes power consumption without compromising performance.

– User-Friendly: Simple and intuitive operation, requiring minimal training.

– Durability: Built to last, with a working life expectancy exceeding industry standards.

– Precision: Delivers accurate results every time.

– Fully Automatic: Reduces manual intervention and increases efficiency.

– Quiet Operation: Operates silently, ideal for both indoor and outdoor settings.

Technical Specifications

– Power Supply: 380V, 50Hz, 3 phase

– Production Rate: 0-20 meters per minute

– Roller Material: High-quality 45# steel

– Number of Roller Stations: 18 stations (configurable based on design requirements)

– Shaft Material: 45# steel

– Shaft Diameter: 70mm

– Main Motor Power: 5.5kW

– Hydraulic Motor Power: 5.5kW

– Cutting Mechanism: Hydraulic cutting with Cr12 blades

– Frame Material: 350 H steel

– Middle Plate Thickness: 16mm

– Drive System: Chain-driven

– Material Thickness: Suitable for raw materials ranging from 0.3mm to 1.0mm

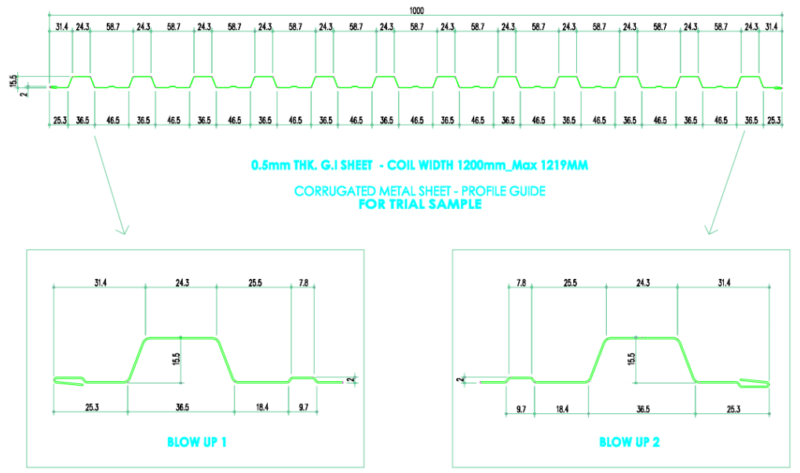

Profile drawing:

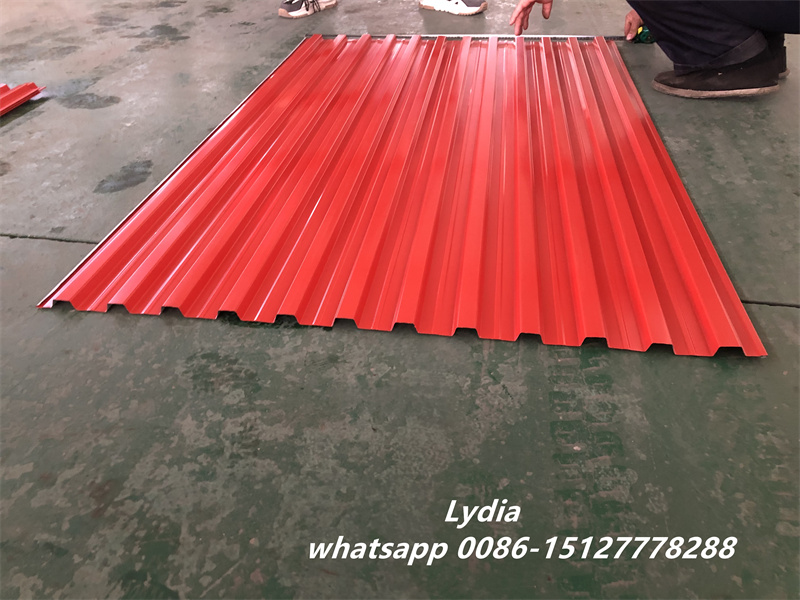

Finished Product Pictures:

Application pictures of rolling shutter door structures:

Warranty

The machine comes with an 18-month warranty, providing peace of mind and ensuring customer satisfaction. This comprehensive warranty covers any defects in materials or workmanship, allowing users to focus on their operations without worrying about unexpected maintenance costs.

By integrating advanced technology and high-quality components, this Australia-style roller shutter door roll forming machine offers a reliable and efficient solution for manufacturers seeking to produce top-tier shutter doors. Its seamless integration with the electric seaming machine ensures that each door is not only durable but also aesthetically pleasing, making it an excellent choice for various applications, including commercial and residential settings.

This rephrased version maintains the original information while enhancing readability and logical flow, ensuring that the text adheres to professional writing standards.

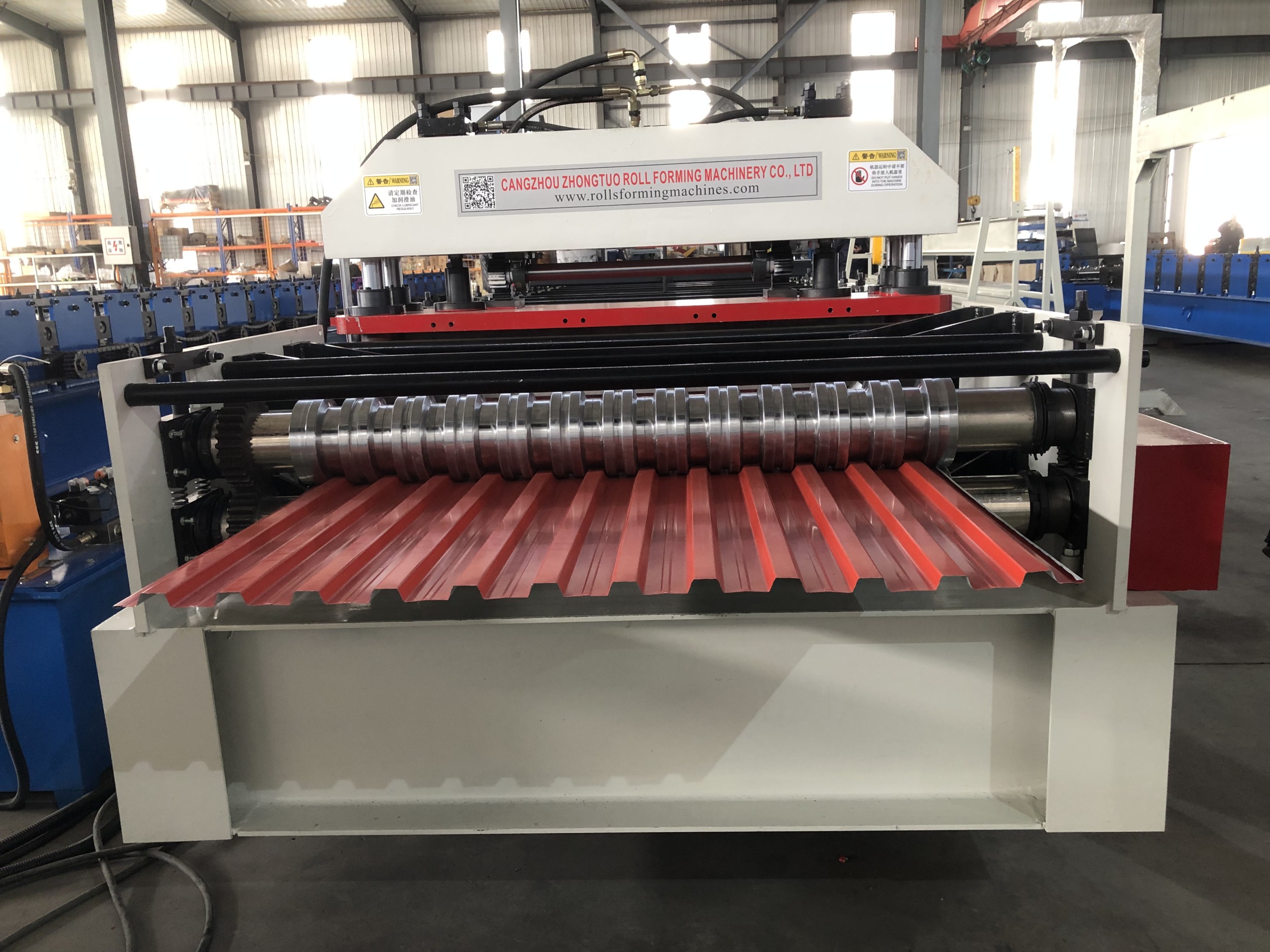

More Pictures Of The Machine:

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP