Features and Advantages of the Solar Photovoltaic Support Rolling Machine

– The machine is designed to handle both light and heavy-duty roll forming applications.

– It features interchangeable spacers, enabling the production of profiles in various sizes.

– Equipped with an inline flexible punching system, it enhances overall production efficiency.

– Options for both pre-cutting and post-cutting are available to suit different production needs.

– The machine operates at a speed range of 12 to 15 meters per minute.

– It adheres to European quality standards and is CE certified, with several patents granted.

– Machines are readily available in stock for quick delivery, ensuring minimal lead time.

Suitable Coil Sheet Materials for the Solar Panel Rack Forming Machine

– Compatible materials include cold and hot rolled steel, as well as galvanized steel.

– Thickness range: 1.5 to 3.0 mm.

– Yield strength specifications: 230 to 300 MPa.

– Width is customizable according to profile requirements.

Advantages of the Solar Bracket Roll Forming Machine

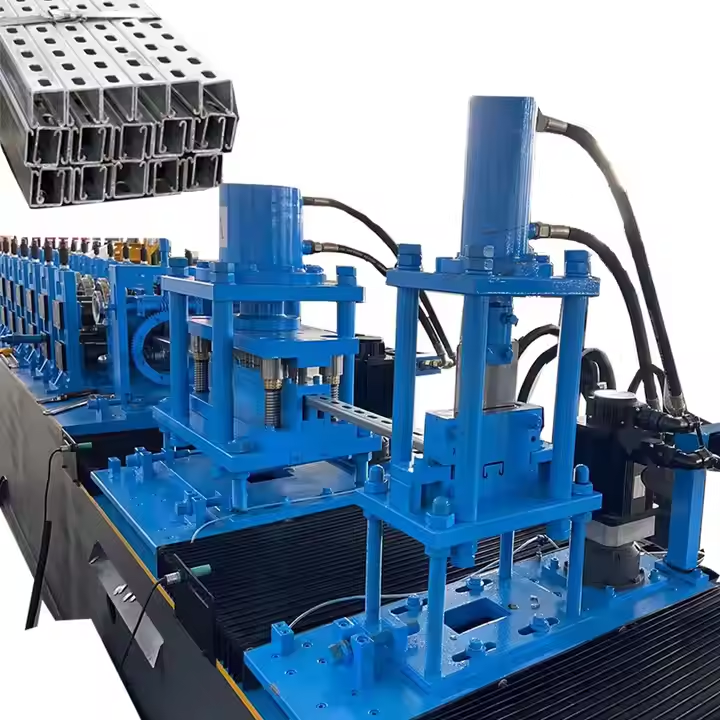

The solar bracket production line is engineered to efficiently manufacture high-quality solar PV supports with enhanced productivity. It features an intuitive PLC control system that enables fully automated operation for ease of use. The machine is fitted with GCr15 rollers, which are treated through a quenching process to achieve a hardness of HRC 60-65, ensuring durability and precision. Additionally, it incorporates a tracking cutting system with Cr12 cutting blades, ensuring clean, accurate cuts for optimal results.

Solar mounting bracket Drawing:

Applications of Photovoltaic Brackets

Photovoltaic brackets, crafted from double-in-roll C-shaped steel and other durable building materials, are gaining popularity due to their eco-friendly, robust, cost-effective, and long-lasting properties. These brackets are designed for quick and easy installation while also offering an aesthetically pleasing look. They are suitable for a wide range of applications, including:

– Light steel structure construction

– Shelving systems

– Ceiling frameworks

– Various other structural supports

The design of solar brackets allows for adjustable angles, helping to optimize local solar energy utilization and maximizing the power generation efficiency of solar panels. In addition, thorough analysis and practical assessments of connection techniques, material selections, and load-bearing capabilities significantly improve the physical performance of photovoltaic modules. This includes enhancing resistance to seismic activity, high winds, snow loads, and corrosion, ensuring that solar modules can be effectively deployed across a broader range of environments and applications.

Strut Channel Roll Forming Machine Working Flow:

The Technical Specifications Of the strut channel Roll Forming Machine :

|

Strut Channel Forming Machine |

|||

| Series | Details | Parameter | Comment |

| Material | Raw material | Galvanized steel | Customer confirmed |

| Material thickness | 1-2 mm | ||

| Decoiler | Roller station | 9 rollers | The standard one to match the production line |

| upper 3 + down 4 to level the coil | |||

| Loading capacity | 3 Ton | ||

| Coil inner diameter | 450-550 mm | ||

| 80 Ton punching machine & punching dies

|

Power: | 80 tons mechanical press power | |

| 15 holes punching mold | |||

| Speeds: | 45 times /min, 8-10 m/min | ||

| Include punching mold: | mold material SKD-11 | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 40 Cr with tempering treatment | ||

| Shaft diameter | 80 mm | ||

| Roller material | Gcr15, some are Cr12 HRC 56-58 | ||

| Rolling station | 18 stations | ||

| Work speed | 45 times /min, 8-10 m/min | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Cast iron mold frame (very strong frame) | ||

| Bearing | Chinese famous brand Harbin | Famous brand of Harbin | |

| Work power | 5.5kw*2, 7.5kw*2 | ||

| Transmission | Gear box transmission | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new!

|

|

| Decoiler, we can change to hydraulic one if you need. | |||

More detailed pictures of the machine:

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP