Here are the versions for South America customers:

Double Layer Roll Former

PBR profile drawing

Material thickness:0.4mm-0.6mm

Feeding width:1066mm/1092mm

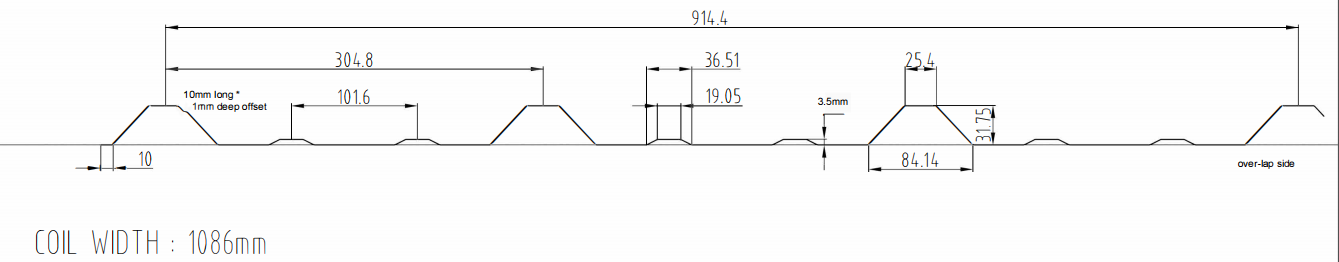

AG Panel profile drawing

Material thickness:0.4mm-0.6mm

Feeding width:1038mm/1092mm

Double layer roofing sheet machine pictures:

Double Layer Roll Former

Ag PBR Double Layer Roll Former and Double Layer Roofing Machine for South America

The Ag PBR Double Layer Roll Former are ideal pieces of equipment designed to produce two distinct styles of roofing tiles, catering to customers with limited space. While these machines offer the flexibility of creating different tile types, they operate one tile profile at a time, ensuring precise and efficient production. Tile profiles can be customized to meet individual customer requirements.

Durability and Efficiency with Clutch Device

These advanced machines feature a clutch mechanism, which prevents simultaneous operation of the upper and lower layers. By reducing drum wear, this innovative design significantly extends the lifespan of the Ag PBR Double Layer Roll Former and Double Layer Roofing Machine, making them reliable choices for long-term use.

Key Advantages of the Ag PBR Double Layer Roll Former

User-Friendly Design for Easy Operation

- Equipped with handrails for effortless coil width adjustment and supporting rollers for stable material feeding.

- Two plastic bands on the platform, along with pinch plates, prevent surface damage to the material and ensure smooth and rapid feeding.

- Hand wheels allow convenient adjustment of the feeding size, optimizing efficiency.

- A manual cutter facilitates easy cutting at any stop point, enhancing operational flexibility.

- Both the upper and lower layers of the Double Layer Roofing Machineand Ag PBR Double Layer Roll Former are equipped with manual cutters to streamline material feeding and cutting.

- Rubber rollers ensure smooth material feeding, while external gears synchronize the movement of upper and lower shafts for efficient operation.

- Dual gears on each layer allow passive-to-active axis operation, delivering more power and faster processing speeds.

- Rollers, spacers, and shafts are meticulously numbered for easy maintenance.

- Internal ball bearings enable synchronized roller movement, increasing operational speed.

- Rollers are coated with a 3mm thick chrome layer to enhance hardness and resist rust, surpassing the 1-2mm coating used by some manufacturers.

Additional Features

The Ag PBR Double Layer Roll Former and Double Layer Roofing Machine are designed with a focus on durability and efficiency, ensuring they serve as valuable tools for generating consistent returns. Optional protective covers are also available upon request to meet specific safety requirements.

For detailed specifications and further customization options, feel free to contact us anytime. Our team is ready to assist you in selecting the best solution for your roofing sheet production needs.

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP