ZTRFM Door Frame Roll Forming Machine

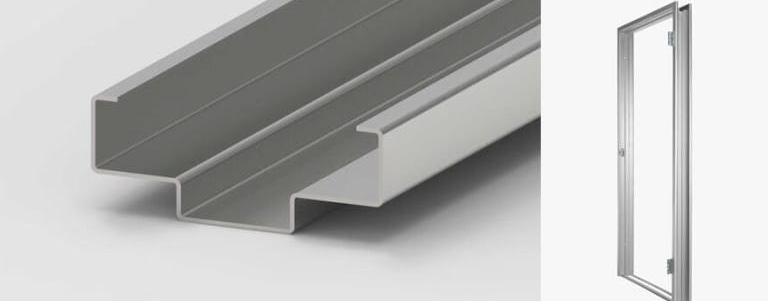

The ZTRFM Door Frame Roll Forming Machine is versatile and designed to manufacture a wide array of metal door frames, including fire-rated, safety, sliding, industrial, and interior doors. This machine can process various types of machinable steel materials, such as zinc-coated steel, galvanized steel, and stainless steel. Among these, the galvanized door frame machine is particularly favored by our customers for its durability and corrosion resistance.

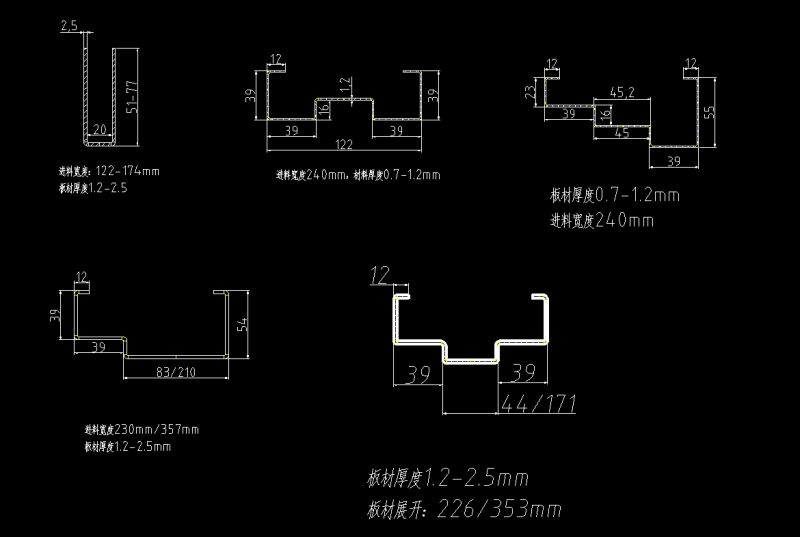

The machine accommodates a thickness range of 0.9 to 1.2 mm for standard applications and 1.2 to 1.6 mm for heavy-duty use, with available gauges including 14, 16, and 18. Below are some commonly requested door frame profiles:

⚫ Double rabbet door frame

⚫ Door rabbet mullion/Transom

⚫ Single rabbet door frame

⚫ Single rabbet mullion/Transom

⚫ Cased openining door frame

⚫ Double egress door frame

⚫ Drywall door frame

⚫ Shadow line door frame

⚫ Standard DELUXE door frame

⚫ Kerfed door frame

At ZTRFM, we tailor our solutions to meet the specific drawings, tolerances, and budgets of each customer. Our professional one-to-one service ensures that the machine is adaptable to your unique requirements. Regardless of the line you choose, Zhongtuo Machinery’s commitment to quality guarantees that you will receive precisely functional and reliable door frame profiles.

Multi-Size Door Frame Roll Forming Machine – Heavy Duty

The Heavy Duty Multi-Size Door Frame Roll Forming Machine is specifically engineered to produce robust and stable steel window and door frames. This versatile machine can handle a variety of materials, including galvanized steel, carbon steel (CS), stainless steel, and copper, among others. The most popular choice among customers is the galvanized steel door frame machine, widely used in both residential and commercial construction projects.

Key Features:

– Material Compatibility: Suitable for galvanized steel, carbon steel, stainless steel, copper, and other metals.

– Width Flexibility: Capable of producing door frames with widths from 120 mm to 250 mm, adaptable to various country standards.

– Power and Durability: Equipped with a gearbox and electric motor for reliable operation, and 80 mm diameter shafts for long-lasting performance.

– Customization: Tailored door frames to match specific wall types and door dimensions, with no limitations on profile types.

– Versatility: Ideal for both residential and commercial applications, with a focus on solid and stable construction.

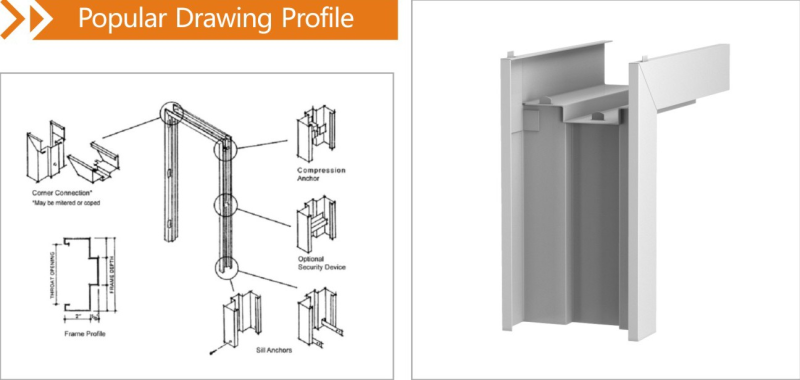

Profile drawing:

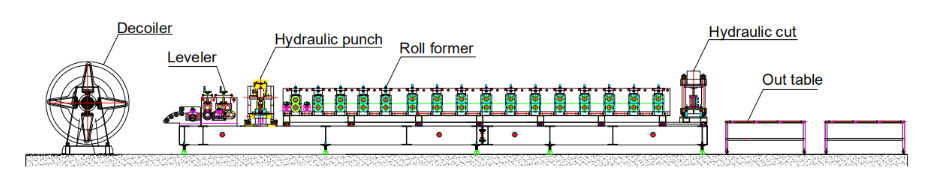

Flow chart:

The Technical Specifications Of Door Frame Machine:

| Series | Details | Parameter |

|

Product sheet |

Raw material | Galvanized steel |

| Material thickness | 0.9-1.2mm | |

| Sheet cutting length | Adjustable | |

|

Decoiler |

Work type: Passive type, Expand and shrink manually | |

| Structure:Steel channel welded for the basic frame | ||

| Usage:To support the coil and make the uncoiling, need the forklift or overhead crane to carry the coil on decoiler | ||

| Loading capacity: 3 tons | ||

| Inner diameter: 450-550mm (manual adjustment) | ||

| Manual brake system, with big hand driving wheel, easy to operate | ||

|

Rolling shaft |

Shaft material:45# STEEL | |

| Shaft type: solid shaft | ||

| Shaft diameter: 60 mm | ||

| Roll forming machine | Tempering treatment to prevent deformed and improve hardness | |

|

Roller |

45# steel | |

| 0.03mm Chromed treatment, make the rollers more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | ||

| Rolling station | 18 rolling stations | |

| Work speed | 0-15 m/min | |

| Machine structure | Carbon steel welded structure | |

| Machine basic frame | 300# H steel welded | |

| Anti rusty treatment after welding | ||

| Work power | 11+11 kw | |

| Rolling spacer | Anti rusty treatment | |

| Steel bar | Anti rusty treatment | |

| Transmission | By gear | |

| Control system | Frequency brand | Delta (original) |

| PLC brand | Delta (original) | |

|

Hydraulic system |

Work type | Hydraulic cutting |

| Driving method | By pillar type Cylinder | |

| Hydraulic motor power | 5.5 kw | |

| Cutter material | Cr12 with heat treatment | |

| Cutting length tolerance | ±1mm/3m | |

| Cutting feature | Steady and safe working condition | |

More Pictures Of Machine:

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP