Ridge cap Roll Former-12” universal Ridge cap

- Ridge Cap Roll Former – Hems both sides of Cap

- Computer Batch Control

- Hydraulic Shear

- Includes 5,000 lb. manual un-coiler

- Loaded on your truck.

- 220V 3 phase

- Weight 8000 lbs., size 21′ x 4′ x 3′

The Metal Roof Ridge Cap Roll Forming Machine is an economical and intelligent solution for producing various ridge cap profiles used in roofing systems. This type of machine offers excellent value for manufacturing ridge caps in diverse shapes and sizes, ensuring high efficiency and durability. Investing in a quality roof bending machine can significantly improve production quality and speed.

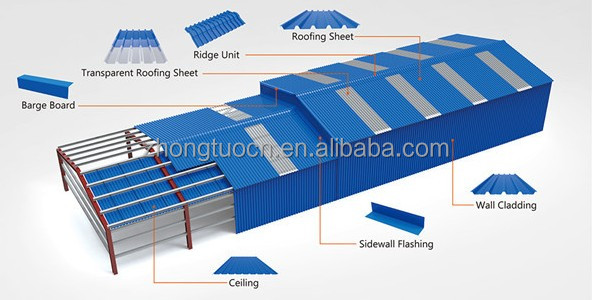

Ridge flashing plays a crucial role in sealing the apex where two sides of the roof meet. As an essential component of any profiled clad building, it provides a seamless, lightweight, maintenance-free, and completely weatherproof finish to the roof. Without proper flashing, rainwater could penetrate the building’s interior, running down chimneys or higher roof areas, potentially causing water damage where the roof is compromised. Flashing not only ensures a watertight seal but also enhances the roof’s aesthetics.

The Application of The finished product:

Details Of Roof Ridge Cap Roll Forming Machine

Roof ridge forming machines are specifically designed to produce ridge caps compatible with steel roofing sheets. Some machines create standard ridges with flat legs that require trimming to fit trapezoidal roofing sheets during installation. Alternatively, special ridge caps can be pre-cut to align seamlessly with trapezoidal sheets, eliminating the need for additional trimming. This design significantly boosts installation efficiency and ensures a perfect waterproof match with roofing panels.

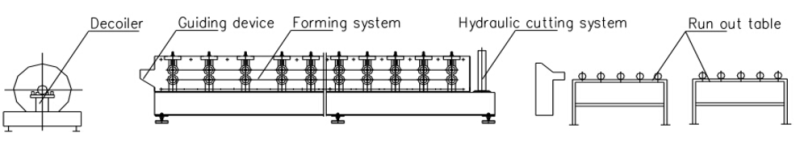

Popular models of ridge cap roll formers include the “stop-to-cut” machine with a working speed of approximately 12-15m/min and hydraulic fly-cutting models that can reach speeds of about 20m/min. The ZTRFM ridge cap forming machines typically include a 5-ton manual decoiler, a forming unit with post-cut features, a PLC controller, a hydraulic station, and a run-out table. Advanced control systems, such as Mitsubishi or Siemens, enhance user convenience—users simply input length and quantity specifications, and the machine automates the process.

Additionally, these forming machines are low-maintenance, requiring only periodic lubrication of the cutting frame to ensure smooth daily operations.

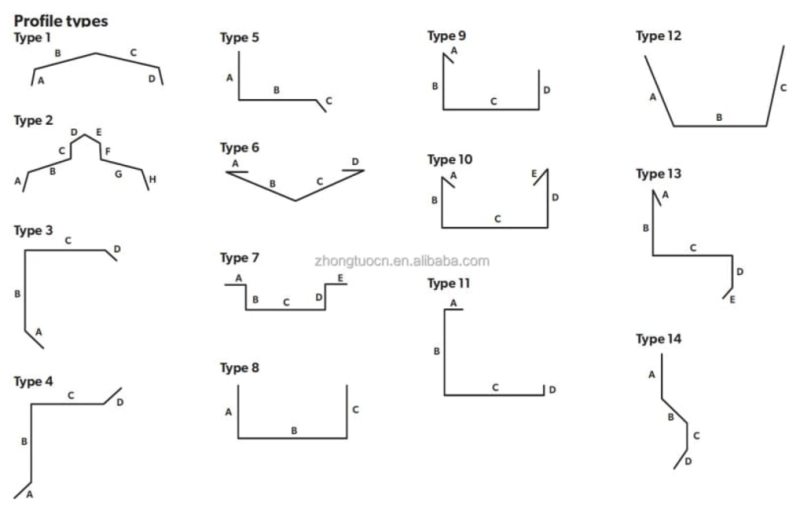

Profile drawing:

Working flow:

The Technical Specifications Of The Ridge Cap Machine Machine:

| NO | Name | Specifications |

| 1 | Raw material | Galvanized steel |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5 ton manual decoiler |

| 4 | Roller station | 22 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 70 mm |

| 7 | Work speed | 0-15 m/min |

| 8 | Transmission | by double chains transmission |

| 9 | Motor power | 5.5 kw motor |

| 10 | Machine frame | 350# H steel welded |

| 11 | Cutting type | Hydraulic fly cutting |

| 12 | Cutting blade material | Cr12 with quenched treatment |

| 13 | Hydraulic motor power | 3KW |

| 14 | Control system | PLC |

| 15 | Brand | PLC:Delta/Siemens/Mitsubishi

Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

More Pictures of the Machine:

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP