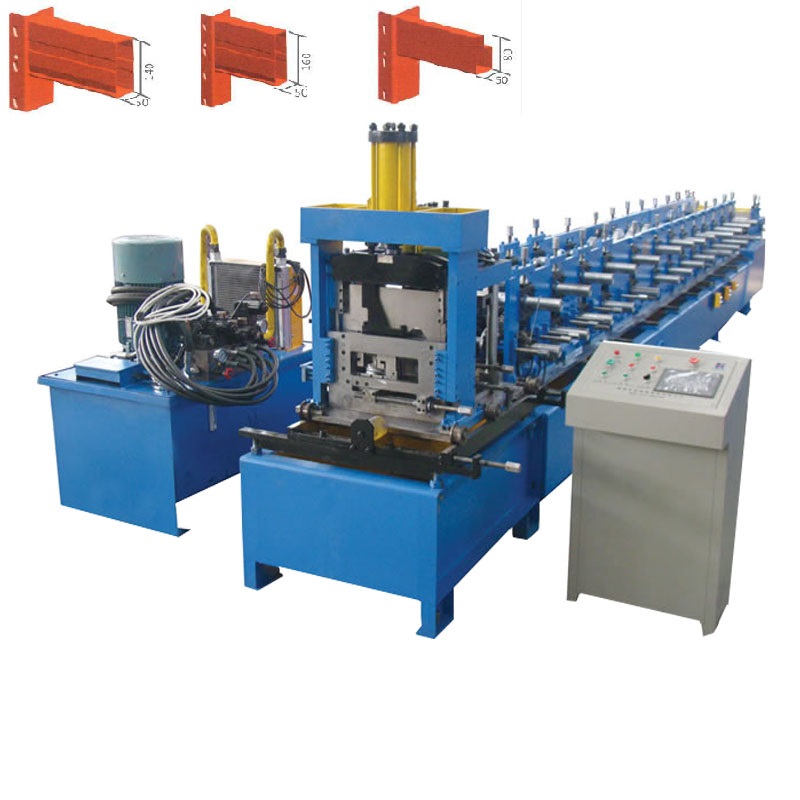

Box Beam Making Machine Description

The Shelf Beam Forming Machine is a specialized piece of equipment designed to manufacture C-shaped beams, which are integral components of shelving systems. These C-beams are widely utilized in storage facilities, supermarkets, shopping malls, and retail outlets for the display and storage of goods on light-duty shelves.

This cold-formed forming machinery can produce a variety of shelf components, including shelf columns, beams, struts, and laminates. The machine operates with PLC (Programmable Logic Controller) automation, guiding the entire molding process from automatic coil unwinding, guiding, and leveling, through feeding, continuous bottom-hole punching, shaping, sizing, cutting, and finally, collecting the finished product on a receiving table.

The Technical Specifications Of the Box Beam Roll Forming Machine:

|

Warehouse rack Box Beam Roll Forming Machine |

|||

| Series | Details | Parameter | Comment |

| Material | Raw material | Galvanized steel | Customer confirmed |

| Material thickness | 1.5-2 mm | ||

| Decoiler | Loading capacity | 5 T | The standard one to match the production line |

| Coil inner diameter | 450-550 mm | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 45# steel with tempering treatment | ||

| Shaft diameter | 60 mm | ||

| Roller material | Gcr12 material with quench treatment | ||

| Rolling station | 16 stations | ||

| Work speed | 20-30 m/min | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Steel plate welded | ||

| Bearing | Roller bearing | Famous brand of Harbin | |

| Work power | 11kw+11 kw (two motors driving) | ||

| Transmission | 1.5 inch Chain drive | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new! | |

| Decoiler, we can change to hydraulic one if you need. | |||

Key Features of the Machine:

- PLC Automation and Safety: The machine is controlled by a PLC system that ensures precise operation and incorporates multiple safety features to protect operators during production.

- Robust Frame Construction: The machine bed is constructed from welded steel plates and undergoes tempering to relieve internal stresses, preventing deformation and ensuring long-term stability.

- High-Strength Forming Frame: Utilizing a cast iron structure that has been tempered, the forming frame offers exceptional strength and durability, contributing to the longevity of the machine.

- Premium Roll Shaft Material: The roll shafts are made from 40Cr alloy steel, which is hardened to achieve a hardness level of HB280, providing superior wear resistance.

- Durable Forming Dies: The dies used in the forming process are crafted from GCr15 steel, quenched to reach a hardness range of HRC56-62, ensuring they can withstand rigorous use without compromising on quality.

- Gearbox-Driven Transmission: Each forming station is equipped with its own gearbox, facilitating smooth and reliable power transmission. This design supports the machine’s ability to operate continuously under high-intensity conditions, extending its service life.

A box beam roll forming machine, sometimes referred to simply as a box beam machine, is a specialized apparatus designed for the production of box beams. These beams, characterized by their rectangular or square cross-sectional shape, are favored in sectors like construction, storage solutions, and structural frameworks because of their robust strength and stability.

Profile Drawings:

Production Line:

Product Details:

5t Hydraulic Decoiler:

3.0kw hydraulic power for expanding

3.0kw electric power for driving

Feeding Part:

Main roll forming machine:

Hydraulic Cutter:

This machine adopt servo tracking shearing type, the speed is fast, when do the shearing the machine will keep running.

Transmission table:

Interlock Machine:

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP