The upright rack making machine, also known as a pallet shelf roll forming line, is specifically engineered for producing shelving and racking components. This advanced steel storage racks making machine efficiently manufactures uprights in various sizes, with typical material thicknesses ranging from 1.5 mm to 3.0 mm. The production process integrates decoiling, servo feeding, punching, roll forming, shearing, and other operations into a seamless automated workflow.

ZTRFM Upright Roll Forming Machine

The ZTRFM upright rack making machine stands out with these notable features:

- Adaptable for multiple sizes with options for either manual or automatic size adjustments.

- Constructed with high chrome-coated bearing steel (EN31) and premium-quality tool steel (D3).

- Equipped with an overflow coolant system to ensure high-quality surface finishes.

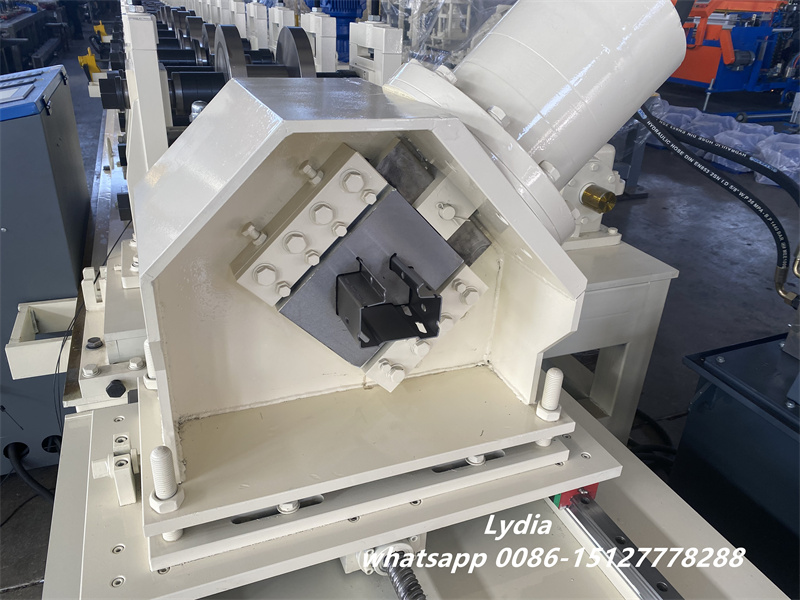

- Features a hydraulic cutting press system for precise operations.

- Employs a closed-loop control system for accurate cut-to-length performance.

- Designed for quick installation with aviation plugs, enabling easy connections and disconnections.

As a state-of-the-art steel storage racks making machine, the ZTRFM model is ideal for high-efficiency production while maintaining exceptional precision.

Upright Rack Roll Forming Machine

Key Benefits of the ZTRFM Upright Roll Forming Machine

- Extended roller lifespan due to specialized roller kits for various sizes.

- Enhanced productivity through uninterrupted operation.

- Maintains tighter tolerances for precise components.

- Simplifies installation and reduces maintenance requirements.

By integrating the upright rack making machine into your production line, you can achieve continuous operation and high-quality results with reduced downtime. ZTRFM provides tailored solutions to meet diverse client needs, adapting to specific drawings, tolerances, and budgets. Alongside upright production, ZTRFM also offers roll forming lines to produce matching box beams, step beams, and shelf panels, ensuring a complete pallet racking system.

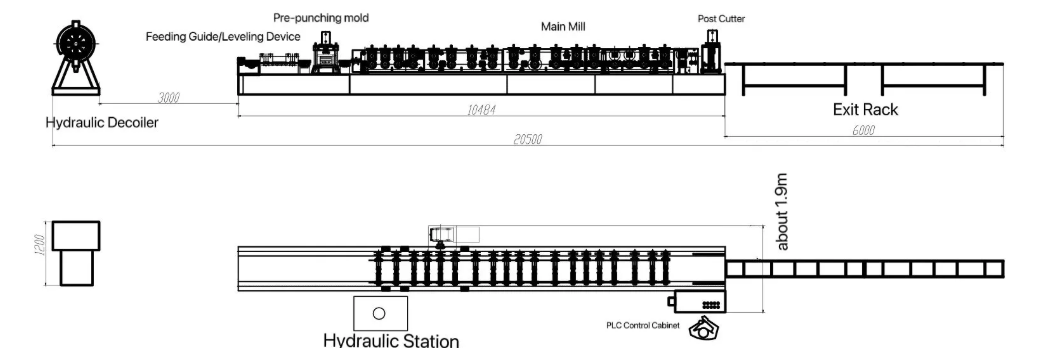

Layout and Specifications of Upright Roll Forming Machines

Upright Rack Roll Forming Machine

Main Categories of Upright Roll Forming Machines

The steel storage racks making machine can be categorized into three primary types:

- For Light Shelving Systems (e.g., Z Beam Rivet Shelving).

- For Medium Shelving Systems.

- For Heavy Shelving Systems.

Light Shelving Systems

- Specifications: Columns approximately 2 m in height and 38×38 mm in size, with each layer supporting 100–150 kg.

Medium Shelving Systems

- Specifications: Uprights measuring 80×40 mm, with a height of 2 m and each layer capable of bearing 200–250 kg.

Heavy Shelving Systems

The uprights for heavy shelving systems are typically produced using the upright rack making machine, ensuring precision and durability. These uprights vary based on customer requirements but generally fall into the following categories:

- Column A: 80×60 mm, height < 3.5 m, layer capacity < 2 tons, and total load ≤ 8 tons.

- Column B: 90×67 mm, height < 5.5 m, and overall load ≤ 12 tons.

- Column C: 100×70 mm, height < 7 m, and total capacity between 12–16 tons.

- Column D: 120×95 mm, height > 7 m, and overall load ≤ 20 tons.

With the steel storage racks making machine, manufacturers can achieve high efficiency and cost-effective production of upright columns for light, medium, and heavy shelving systems.

Upright rack Roll Forming Machine working flow:

Hydraulic Decoiler – Feeding Guide/Leveling Device – Pre-punching mold – Main Mill – Post Cutter – Exit Rack.

Upright Rack Roll Forming Machine

Upright Rack Roll Forming Machine

Upright Rack Roll Forming Machine

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP