Specializations

- Steel framing machines for wall panels, trusses, and floor joists in residential and commercial buildings.

- Prefabricated steel systems for modular construction.

- Framing solutions for low-rise and high-rise buildings.

- Equipment for walls, floors, beams, roofing, and prefabricated modules like kitchen and bathroom pods.

Machine Specifications

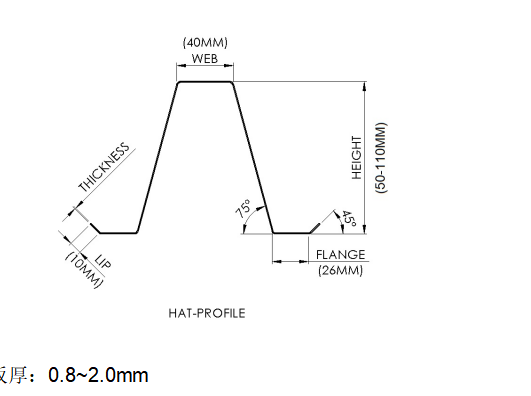

| Type of material to be processed: | C.R. | GI (550 MPA ) | |

| No. of Station | 16 | |

| Length of profile sheet: | No limit | |

| Total connected power required: | 35 Kw. | |

| Coil Width range: | 150mm to 300mm | |

| Coil Thickness range: | 0.80 mm to 2 mm | |

| Coil weight (Allowed on Decoiler): | Up To 5000 Kg. | |

| Production line speed: | Without Cutting & Punching: | 0 to 20 MPM |

| With Cutting & Punching: | 5 to 7 MPM (as per job length) | |

| Automation level in performance | P.L.C. controlled length | |

| Accuracy level | length: ±2 M.M. | |

| BEND/TWIST: 1.5 MM/MTR. | ||

| DIMN:+/- 2 M.M. | ||

Profile drawing:

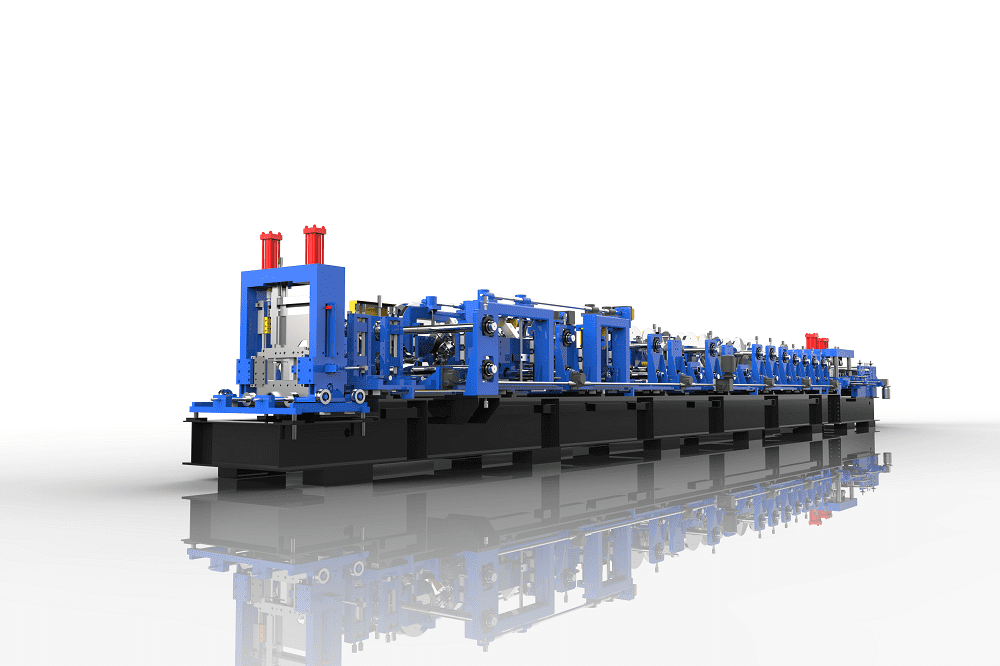

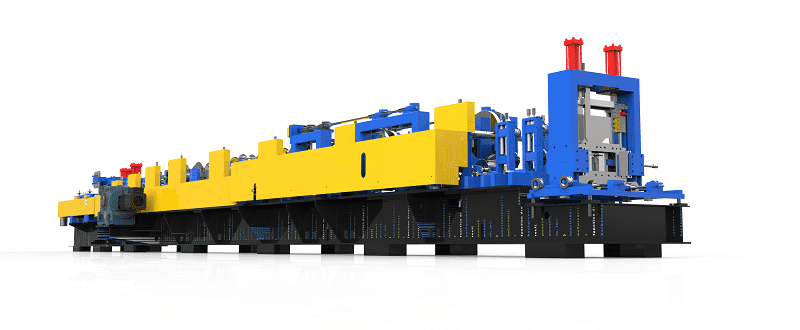

High-Speed Top Hat Section Roll Forming Machine with Servo Flying Cutoff

This machine, exported to Canada, is expertly designed to manufacture steel top hat sections tailored to client specifications. By utilizing the Hat Section Cold Roll Forming Machine, profiles are created with high precision and production speeds reaching up to 15 meters per minute.

The line is controlled by an advanced PLC system, allowing operators to easily input production details such as hole distances and cutting lengths through a touchscreen interface. Once programmed, the machine, including features from the Omega Purlin Roll Former, operates automatically and halts after completing the assigned production.

Why Choose ZTRFM?

ZTRFM is a leader in manufacturing cutting-edge roll-forming machines like the Omega Purlin Roll Former and the Hat Section Cold Roll Forming Machine, designed for the construction of light steel frames and cold-formed steel structures.

Since 2009, ZTRFM has collaborated closely with clients to deliver innovative solutions. By combining advanced technology, robust designs, and easy-to-use systems, ZTRFM ensures its customers stay ahead in competitive markets.

All machines, including the Omega Purlin Roll Former, come with a Windows-based control system compatible with CSV files from various design software, giving clients flexibility and convenience.

ZTRFM is your go-to partner for intelligent manufacturing solutions for multi-story prefabricated buildings, offering reliable, efficient, and versatile machines!

-

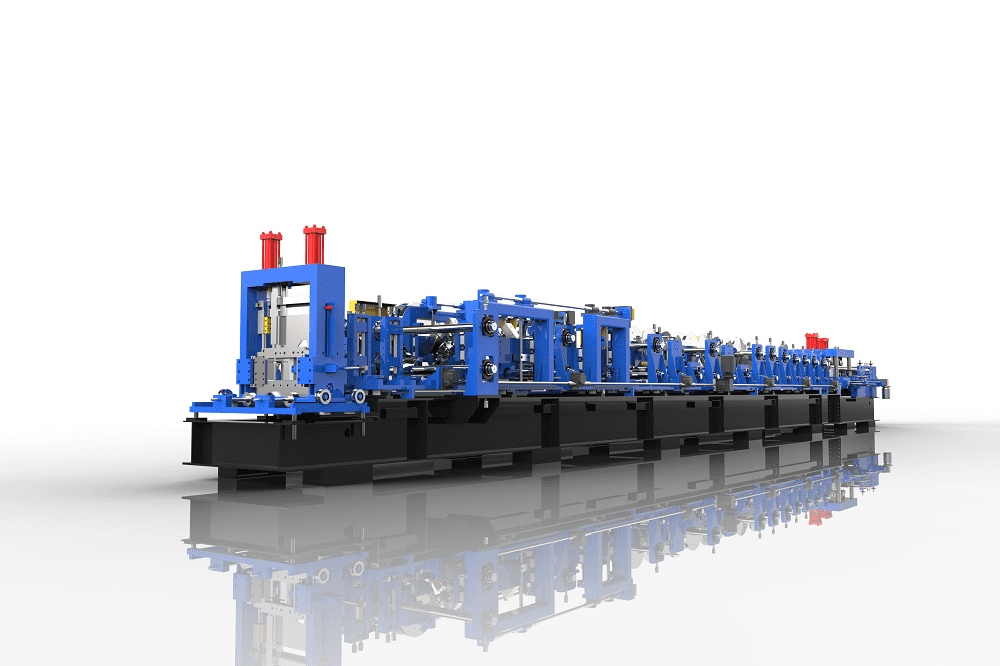

Top Hat Section Cold Roll Forming Machine

More pictures of the machine:

Top Hat Section Cold Roll Forming Machine

Top Hat Section Cold Roll Forming Machine

Top Hat Section Cold Roll Forming Machine

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP