The primary advantages of using steel roof and ceiling battens include:

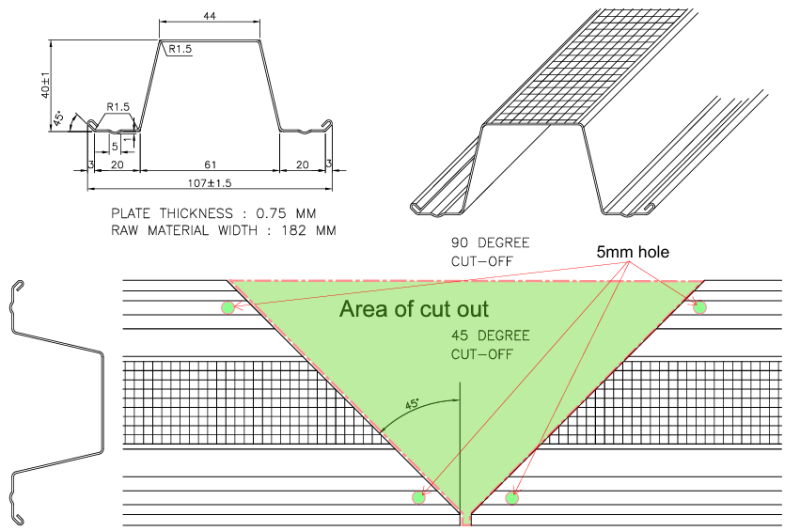

Raw material: GI Hardness G550

Material thickness: coil thickness 0.75mm

45 degree cut to square & straight cut with holes

– Preventing Plasterboard Cracks: roof and ceiling battens help avoid cracks in plasterboard that can occur when directly attaching lining boards to timber.

– Achieving a Flat Ceiling: Even if the underlying timber is uneven, it’s easier to achieve a flat, level ceiling with roof and ceiling battens.

– Noise Reduction: Installing ceiling battens with clips can reduce noise transmission between floors in residential buildings.

– Resistance to Shrinkage: Unlike timber, roof and ceiling battens are less affected by shrinkage, minimizing the risk of lining issues.

– Cost and Time Savings: Reduced maintenance calls save time and money, making steel battens a practical choice for builders.

By offering customizable settings, our roll forming machine can produce battens in various sizes, thicknesses, and profiles, tailored to meet the specific needs of different roofing and Ceiling and Roof Batten Roll Former. Whether you’re working on a small home renovation or a large-scale commercial development, our machine delivers exceptional performance and versatility.

Ceiling and Roof Batten Roll Former:

Our advanced roll forming machine specializes in manufacturing steel Ceiling and Roof Batten Roll Former, commonly known as HAT-shaped purlins. Designed for precision and efficiency, this equipment produces high-quality battens suitable for both residential and commercial applications. The machine’s cutting-edge technology ensures accurate shaping and consistent profiles, delivering reliable and durable components for your projects.

Ceiling and Roof Batten Roll Former

In the construction industry, a batten can refer to a strip of solid material, traditionally made from wood but now available in plastic, metal, or fiberglass. In the context of steel construction, these battens, often called “top hats” due to their profile, serve as furring channels. Our steel battens are manufactured from high-tensile zinc-coated steel, ensuring they remain straight and consistent over their long lifespan. A roof batten roll forming machine actually has another names furring channel roll forming machine or top hat purlin roll forming machine

Profile drawing:

Ceiling and Roof Batten Roll Former

Work Flow:

Decoiler→ Feeding Guide Device → Punching Device → Roll Forming Mill→ PLC System Hydraulic → Hydraulic Post-cutting Device→Exit Rack

The Technical Specifications of Ceiling and Roof Batten Roll Former :

|

ZTRFM Ceiling and Roof Batten Roll Former |

||

| 1.Formed Material | GI Hardness G550 | Thickness:0.75 mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 14 rollers |

| Diameter of shaft | 50 mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | Gearbox transmission | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Weight | About 6T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 11 KW*2 setswith energy accumulator, so with more power to make the shearing more fast. |

| Servo power | 2.3 KW | |

| 6.Voltage | 415V 3Phase 50HZ | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | Max 40m/min(customized) | Speed is adjustable according to customer’s request |

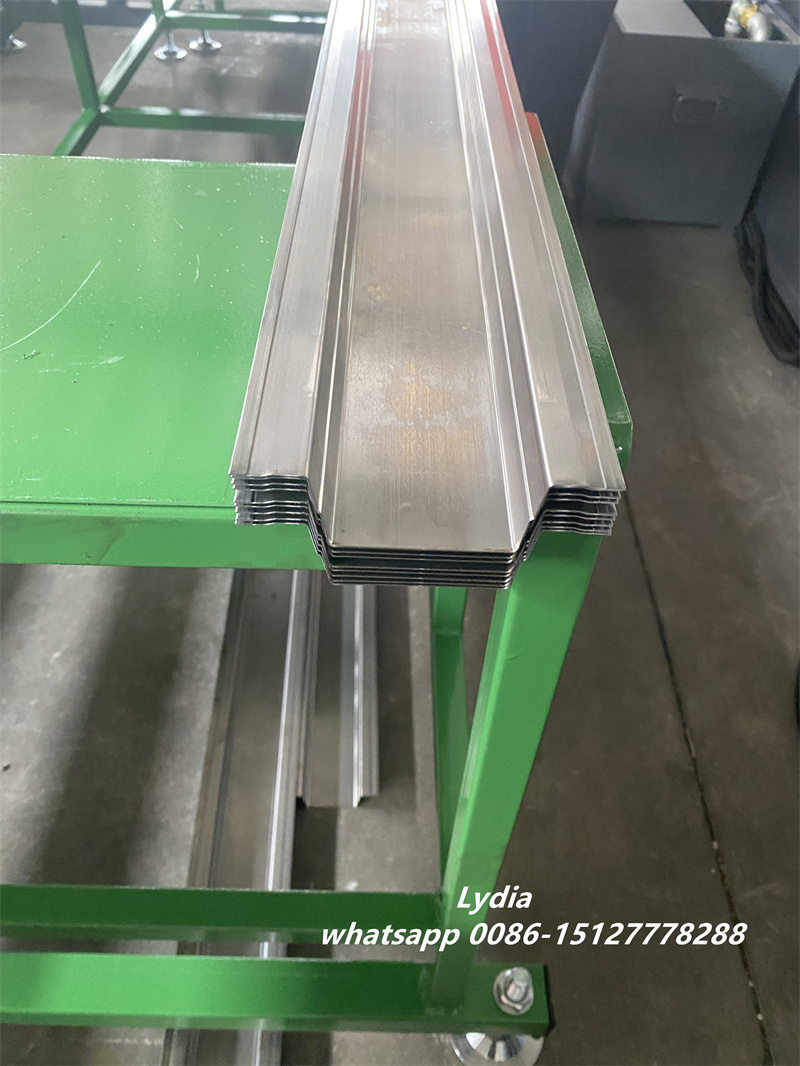

More pictures of the machine:

Ceiling and Roof Batten Roll Former

Ceiling and Roof Batten Roll Former

Ceiling and Roof Batten Roll Former

Ceiling and Roof Batten Roll Former

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP