5V Roll Forming Machine

The Roll Forming Machine consists of three main parts: the feeding section, the forming section, and the cutting section after forming. The resulting panels have a smooth, attractive appearance with excellent strength and long-lasting durability. These panels are widely utilized in both industrial and residential buildings, including factories, warehouses, sports facilities, exhibition centers, theaters, and as exterior surfaces and walls.

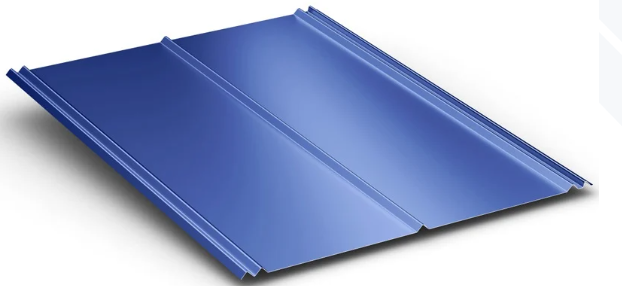

5V-Panel Description

Originally designed for agricultural purposes, the 5V crimp panel has gained popularity in residential applications. You can either mount the 5V machine in your shop or make it portable for use at job sites. This machine is equipped with a hydraulic drive, a front hydraulic scissors shear, and offers adjustable panel width settings ranging from 14″ to 28″. When using the standard 27 1/2″ coil stock, the 5V machine produces a finished panel that is 26″ wide, providing a 24″ coverage area when overlapping.

Profile drawing:

- Hydraulic Drive and Front Scissors Shear

- 40 FPM speed

- Adjustable Width: 12’’-20’’

- 14 Forming Stages

- # 40 Chain and Sprocket / Spur gear drive

- 3 HP Electric-Hydraulic Power Unit, 110V, Single Phase with 16 cu in drive motor

- 416 Grade Stainless Steel Forming Rolls

- Push Button RUN/JOG Controls at Entry & Exit Ends

- Hardened Stainless Steel Forming Roller System with Shear Dies

- Hydraulic Drive & Shear

- Length Control Limit Switch

- Panel Recognition Safety Proximity Switch

- Welded Tubular Steel Frame

- Power Interruption Safety Circuit

- Industry’s Best Warranty

The technical specifications of the 5V Roll Forming Machine:

| NO | Name | Specifications |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

| 4 | Roller station | 18 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by gear box transmission |

| 9 | Motor power | 5.5kw motor |

| 10 | Machine frame | 400H steel welded |

| 11 | Cutting type | Hydraulic cutting |

| 12 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr 12 High Grade Steel |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | PLC |

| 17 | Brand | PLC:Delta/Siemens/Mitsubishi

Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP