Description of CZ Purlin Roll Forming Machine

Cangzhou Zhongtuo offers a variety of purlin and girts forming machines, designed to accommodate profiles ranging from 100mm to 400mm in both Z and C shapes. These machines provide options for cutting to length and can be configured as either punched or unpunched.

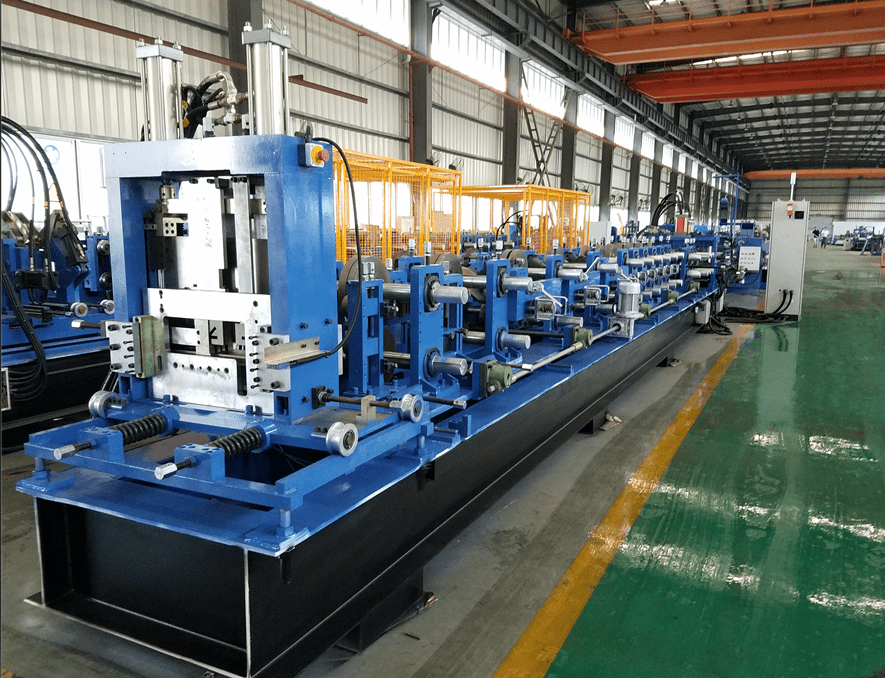

Heavy Duty CZ Purlin Machine

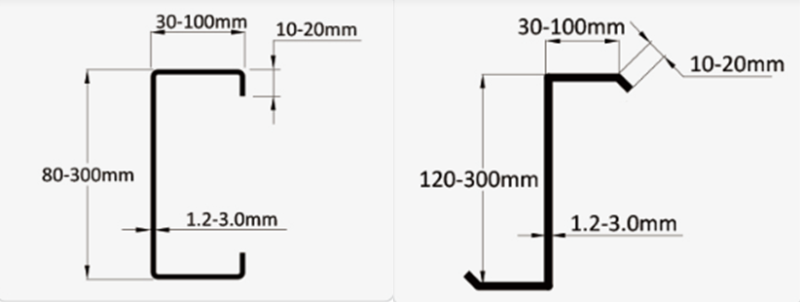

Profile drawing:

Heavy Duty CZ Purlin Machine

Application pictures of prulins structures:

C/Z purlins are widely used in various construction applications, including roofs, trusses, factories, and civil houses. Their lightweight design makes them easy to install and transport, enhancing their appeal in construction projects.

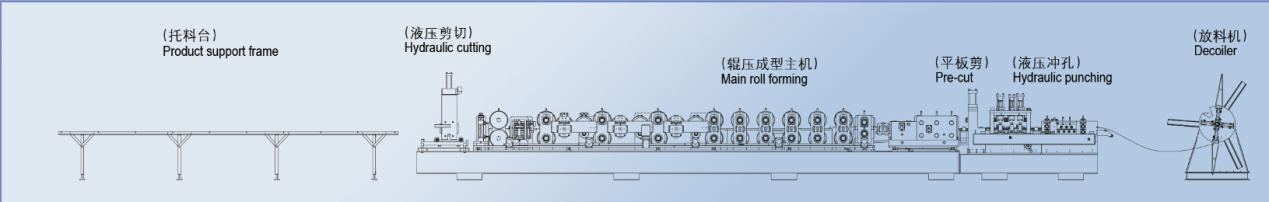

Flow chart: De-coiler – Leveling device — pre- punching and pre-cutting – roll forming parts – stack

Heavy Duty CZ Purlin Machine

Feeding and Leveling Device:

It used for making the material flat before feeding into the roll forming machine.

Heavy Duty CZ Purlin Machine

Features of the Heavy Duty C/Z Purlin Machine:

The C/Z purlin machine is equipped with several components, including a decoiler, feeding and leveling unit, punching system, pre-shear, roll forming section, hydraulic post-cutting system, run-out table, hydraulic station, and a PLC control system. Its standout feature is the quick-change mechanism, utilizing a linear guideway for seamless and efficient adjustments to web sizes.

This machine is designed to produce high-standard products with a yield strength of up to 345Mpa. Its extended production line ensures that the final products have no open ends. Switching between C and Z profiles requires only three steps and can be completed within 5 to 15 minutes, significantly reducing downtime. The innovative design enhances productivity while minimizing labor costs, making it ideal for modern manufacturing needs.

In addition to its efficiency, the machine is user-friendly and delivers stable performance with excellent precision, ensuring reliable operation throughout the production process.

Adopt fast C/Z interchanging system,Quick C/Z interchanging only with 3 steps,within 5 -15 mins.

The Technical Specifications Of Heavy Duty Cz Purlin Machine:

| Heavy Duty CZ Purlin Machine | ||

| 1.Material of coil | Material Thickness | 1.5-3.0 mm |

| 2.Forming system | Rolling Speed | 30m/min( without the cutting time) |

| 3.Main body

|

Roller Stations | About 21 stations |

| Roller Material | Cr12 mould steel | |

| Main Motor Power | 22 kw | |

| Shaft material | 40Cr Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product | |

| Roller | About 21 groups rollers | |

| Material Of Cutting | CR15 with quench treatment | |

| Driven type | By chain | |

| Tolerance | +-1.5mm | |

| 4.Cutter | Cutting way | (Hydraulic Cutting)Adopt our innovative cutting system, CZ integrated & adjustable cutting mold do not need to replace cutting mold when purlin sizes change. |

| 5.Voltage | 380V | Also can satisfy Customer’s require |

| 6.Control system | Control System | PLC Delta |

| Inverter | Yaskawa | |

| Weight | About 13-14 Tons | |

| Table size | 13 m x 1.5 m x 1.7 m | |

| MOTOR | Under the frame of the machine | |

More pictures of the machine:

Heavy Duty CZ Purlin Machine

Heavy Duty CZ Purlin Machine

Heavy Duty CZ Purlin Machine

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP