Roof & Wall Cladding Roll Forming Machine

Total power :5-22kW

Speed:16-46m/min

Dimension (L×W×H) :(9-11)×(1.6-2.2)×1.8m

Weight of machine : 6-12 tons

Roller station :16-24

Material thickness :0.15-0.7mm(G300-G550)

Material width :914,1200,1219,1450mm

Wall cladding machine

Width adjustable wall cladding profile making machine

Width adjustable wall cladding profile making machine is designed to make the wall cladding panel in batch fully automatically. By this kind of profile, the width could be from 420 to 1450mm adjustable. With side hole punching for easy to do the installation but, you can choose add or not. As the length and width both adjustable, you can use it also for ceiling. The nails are hidden in the profile, so the installation will be more beautiful.

Features of such wall cladding profiles:

- PPGI and GI (if you use 550 MPA ,please tell me in advance), support the most common and popular profiles.

2. Support the thickness range:0.4 to 1mm

3. Coil width adjustable 198-728mm.

4. With installation holes punching.

Wall cladding machine

What is a Roof Wall Cladding Roll Forming Machine?

A Roof Wall Cladding Roll Forming Machine is specialized equipment designed to manufacture metal roofing and wall panels. This machine is particularly adept at producing concealed fastening metal wall and fascia panels in an efficient, fully automated process. It is widely used for both new construction and retrofitting existing structures, offering flexibility in design and functionality.

Key Features and Components of Wall Cladding Roll Forming Machine

– Fully Automated Operation:The steel ZTRFM Wall Cladding Roll Forming Machine operates seamlessly with an intuitive Human-Machine Interface (HMI) panel, making it user-friendly.

– Integrated Systems:It includes a decoiler for unrolling metal coils, sheet guiding equipment to ensure proper alignment, a roll forming section for shaping the metal, a Programmable Logic Controller (PLC) for system control, hydraulic cutting mechanisms for precise cuts, and a collection table for finished products.

– Durable Construction:The machine boasts a robust frame that ensures stability and longevity during operation.

Applications and Panel Types

The Wall Cladding Roll Forming Machine is ideal for producing concealed fastening metal wall and fascia panels, which combine the durability of metal with an aesthetically pleasing appearance. These panels are available in both fluted and flat profiles, each suitable for different architectural needs.

– Fluted Panels:Provide a ribbed appearance, enhancing visual appeal and structural integrity.

– Flat Panels:Offer a sleek, smooth finish, perfect for modern designs. The 12.0 Flat Panel series, for instance, features a 1 ¾-inch deep leg, creating an ideal cavity for installing rigid board insulation

Technical Process:

Raw materials uncoile→ Notching→ Continuously cold roll forming→Automatic cutting and folding→Ready product output

| Rolling shaft | Shaft material: 45# steel with quenched treatment, precision machined |

| Shaft diameter: 65 mm | |

| Roller | Roller material: GCR15 steel, finely processed, HRC58-62℃ surface chrome plating |

| Machine structure | Arch frame thickness 35 mm |

| Rolling station | 16 stations |

| Forming speed | 10-20 m/min |

| Machine body | 350H beam steel |

| Bearing | Chinese famous brand Harbin |

| Work power | 5.5 kw servo motor |

| Transmission | By chains |

| Automatic changing size | By servo motor; PLC control |

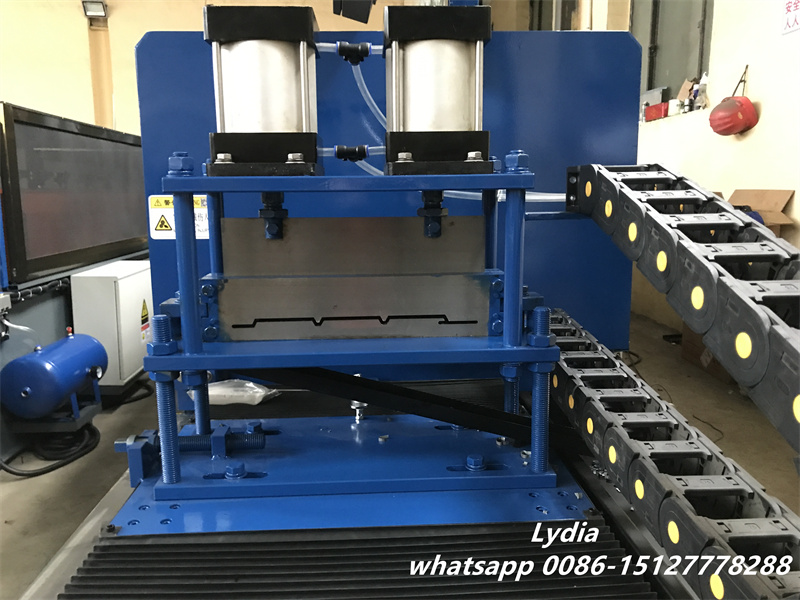

More Pictures of Roof Cladding Making Machine :

Wall cladding machine

Wall cladding machine

Wall cladding machine

Wall cladding machine

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP