Key Features:

- Chrome-treated shafts and wheels

- Profile Drawing Material: Minimum Thickness 0.4mm, Maximum Thickness 0.6mm

- Common Use Material Thickness: 0.5mm for inspection

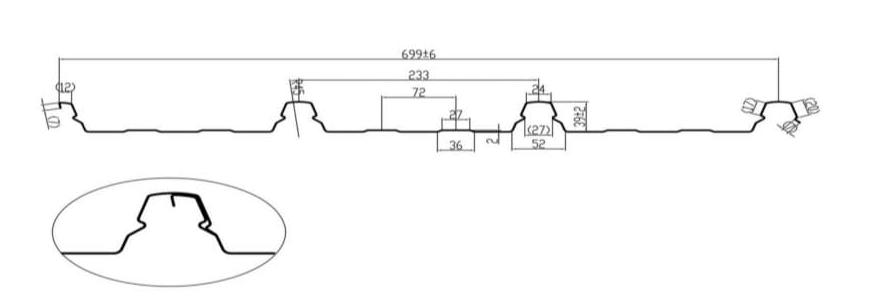

- Effective Width: 700mm; Feeding Width: 914mm

- Pre-painted Coils; Tension Grade: 300-550Mpa

- Machine Weight: 11.5-11.8 tons

- Size: 11.5m × 1.6m × 1.6m

- Cold Rolling Mills with 28 stages to form

By integrating the Photovoltaic/PV Panel Roll Former and the Solar Roof Sheet Roll Forming Machine, businesses can achieve precise manufacturing of solar roof panels, enabling rapid and reliable adoption of renewable energy technologies.

Profile Drawing:

Features and Advantages of the Solar Roof Sheet Roll Forming Machine

- Photovoltaic roof panels produced by the Photovoltaic/PV Panel Roll Formerand Solar Roof Sheet Roll Forming Machine are excellent technological tools for transforming old color steel tile factories into energy-efficient structures.

- Zhongtuo photovoltaic roof panels, manufactured using the Solar Roof Sheet Roll Forming Machine, are categorized into two generations. The first generation seamlessly covers original trapezoidal color steel tiles, while the second generation fits hidden roof panels and corner roof panels.

- These products have passed stringent tensile, waterproof, and anti-corrosion tests in South Korea, ensuring durability and high performance.

- The Photovoltaic/PV Panel Roll Formerhas been instrumental in producing roof panels used in photovoltaic roofing projects for renowned international companies such as Samsung and Hyundai.

- Without removing the original roof structure, the Solar Roof Sheet Roll Forming Machineenables cost-effective and efficient photovoltaic transformation, making it ideal for retrofitting factories into sustainable energy sources.

- This technology offers a sustainable development solution for converting traditional industrial buildings into green energy hubs.

Advantages of the Solar Roof Sheet Roll Forming Machine

- The Solar Roof Sheet Roll Forming Machine is engineered for high-quality production of solar PV supports, improving manufacturing efficiency.

- It features an easy-to-use PLC control system for automated operations, minimizing manual intervention.

- GCr15 rollers, treated via a quenching process to achieve a hardness of HRC 60-65, ensure long-term durability.

- The tracking cutting system with Cr12 cutting blades adds precision to the manufacturing process.

Flow Chart:

Uncoiler → Leveling → Punching → Roll Forming → Cutting → Exit Rack

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP