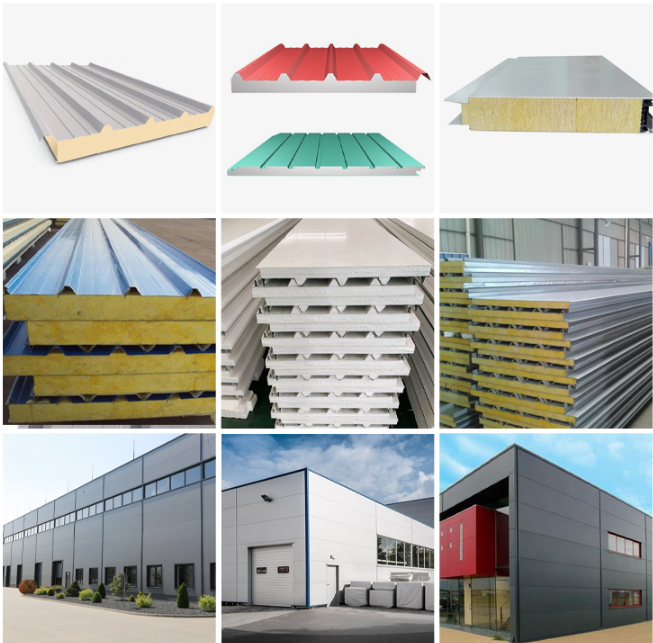

A PU (Polyurethane) Sandwich Panel Production Line is a specialized manufacturing system designed to produce sandwich panels, which are composite materials used extensively in construction and industrial applications. These panels typically consist of two outer layers, often made from metal (like aluminum or steel), color-coated steel, non-woven fabric, kraft paper, or aluminum foil, with a core of polyurethane foam that provides insulation, strength, and other properties.

PU Sandwich Panel Machine

Key Components of a PU Sandwich Panel Line:

- Uncoiling System: For handling and feeding the outer layer materials, such as coils of metal sheets, into the production line.

- Film Covering and Cutting System: Applies protective films on the outer layers if required and cuts them to size.

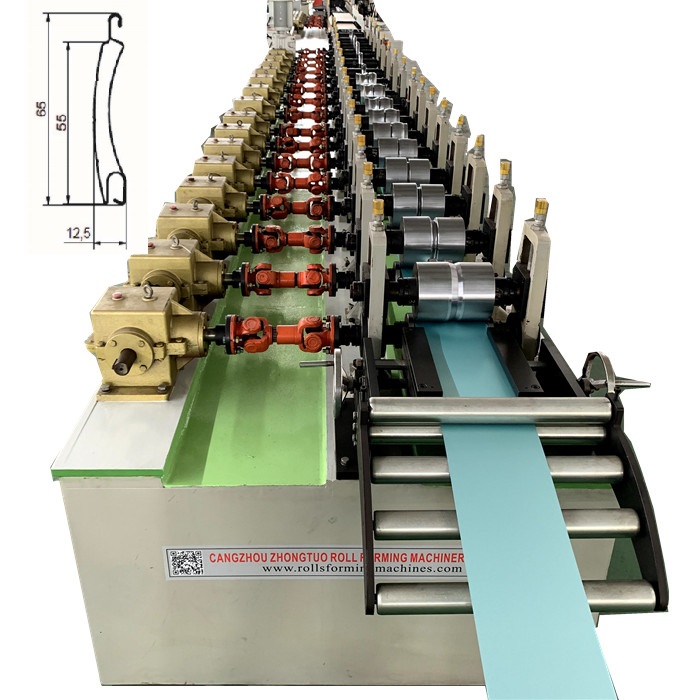

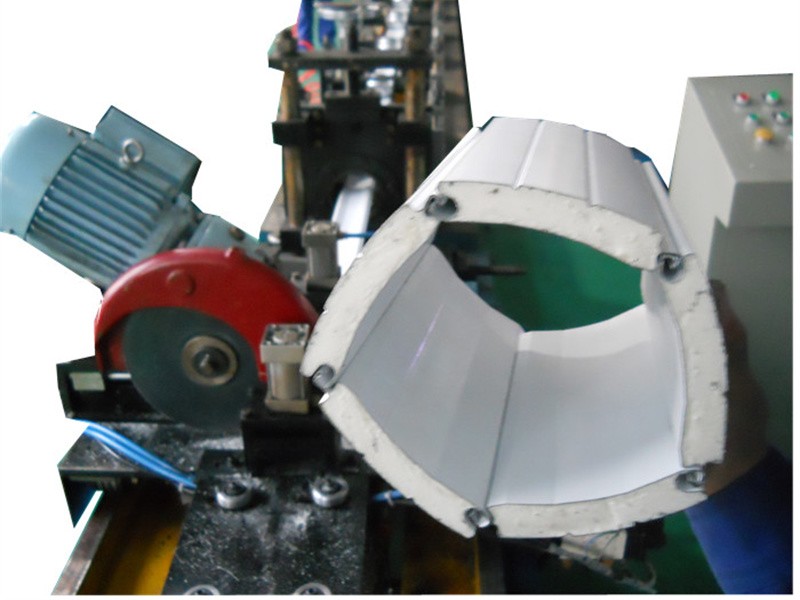

- Roll Forming Machine:Shapes the metal sheets into the desired profile for the outer layers of the sandwich panel.

- Preheating Oven:Heats the outer layers to prepare them for bonding with the core material.

- High Pressure Foaming System:Injects polyurethane foam into the space between the outer layers under high pressure to ensure even distribution and optimal filling.

- Double Belt Conveyor: Transports the panels through the production process while maintaining flatness and preventing deformation.

- Double Belt Heating Device: Assists in the curing of the polyurethane foam by maintaining the necessary temperature.

- Cutting System:Cuts the finished panels to the specified length after the foaming and curing processes are complete.

- Basic information of PU rolling shutter door machine:

- Rolled strip thickness: 0.28mm -0.35 mm

2 .Rolled steel strip material: aluminum plate

3 .Production speed: 8–5 meters

- Straightness error of rolled work piece≤±1.5mm/1500 mm

- Angle error of rolled work piece≤±1.5mm/1000 mm

6 .The fixed length error of the rolled work piece is 10m±1.5mm

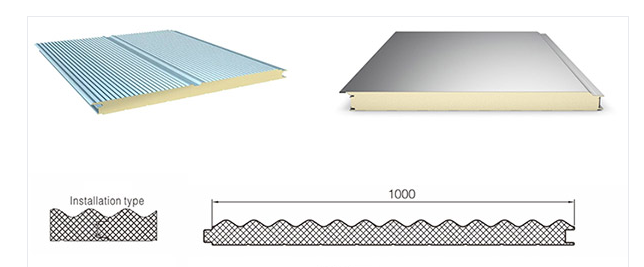

PU/PIR Sandwich Panel Line Panel Drawings:

PU Sandwich Panel

PU Sandwich Panel:

PU Sandwich Panel

PU Sandwich Panel

About Us

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP