Product Profiles Details

The ceiling T-bar roll forming machine is a popular and widely used device. The thickness of the T-bar, commonly known as the T-shaped keel, typically ranges from 0.3mm to 1.2mm, with lengths varying between 3000mm and 6000mm.

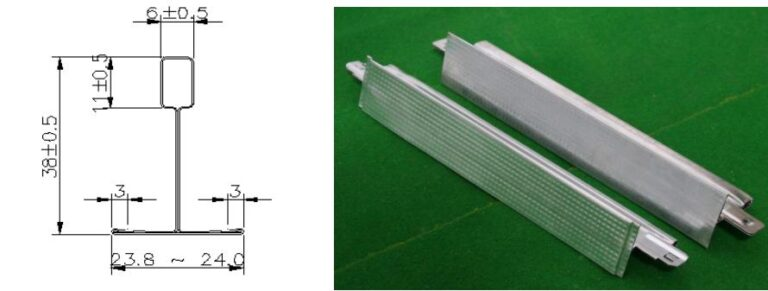

Cross-Sectional Design: The T-shaped keel features a “T” cross-section, where the top width is usually 24mm and the bottom width is approximately 38mm.

Application in Building Decoration: As a frequently utilized material in interior decoration, the T-shaped keel is predominantly applied in suspended ceiling construction.

Key Characteristics:

High Stability: The T-shaped cross-sectional design provides excellent support and ensures secure fixation within the suspended ceiling system.Metal farmings used in concealed grid gypsum ceiling of light weight structure include furring channel,carrying channel,studs,tracks,wall angle,and main frame channel.Ceiling/drywall/furring/C line roll forming machine is used to produce drywall ceiling channels(also called as C line,furring Channel,Drywall Frame) with stable operation by steady frame,speed up to 35m/min and customized design.

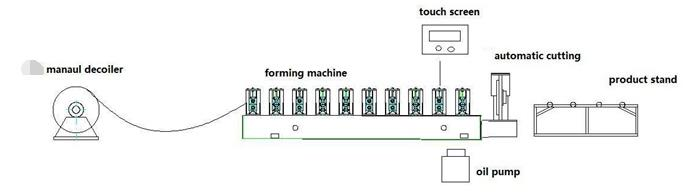

Components of T Bar and T grid production line :

– Decoilers

– Main roll forming machine

– Automatic hydraulic cutting off station

– Hydraulic cooling station and electric control

system, etc.

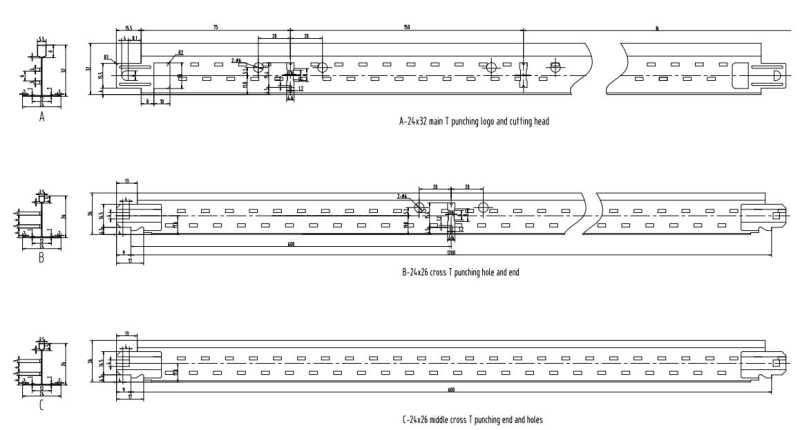

– Main Tee bar size:H38*24mm, H32*24mm

– Length: 3600mm

– Thickness:0.20-0.40mm

– Cross Tee:H26*24mm, H24*23mm

– Length: 1200mm, 600mm

– Thickness:0.20-0.40mm

In addition, ZTRFM provides a variety of completely automatic metal drop ceiling tile production lines for the creation of ceiling boards in various sizes, including 600*600mm, 300*300mm, and 600*1200mm. These machines’ metal ceiling tiles can be made into an entire exposed metal ceiling suspending system.

Profile drawing:

How to do the installation of Suspended Ceiling?

This installation method is perfect when access to overhead electrical wiring, pipes or duct work is needed.

This installation method is perfect when access to overhead electrical wiring, pipes or duct work is needed.

Impeccable profiles and connectors whatever the speed

The ZTRFM roll forming systems offer a complete range of production plants and roll formers for the manufacture of T-bars (cross tee and main runner) for supporting suspended ceiling panels. Like all ZTRFM production systems, the range is available in various versions according to the required type of profile, output and level of automation.

After-Sales Service for Ceiling T-Bar Roll Forming Machine:

- Scheduled International Follow-Ups:Dedicated after-sales teams will conduct regular overseas follow-ups to assess product performance and gather customer feedback.

- Remote Video Assistance for Maintenance:Offer troubleshooting and maintenance support to international clients via video consultations, ensuring timely resolution of issues.

- Two-Year Warranty Coverage:The ceiling T-bar roll forming machine is backed by a two-year warranty for quality assurance

The Technical Specifications Of The Ceiling T grid Machine:

| ZTRFM Ceiling T grid Machine | ||

| 1.Formed Material | GI | Thickness:0.15-0.4mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 18 rows for the main T

16 roller station for the cross T bar |

| Diameter of shaft | 50 mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | Gearbox transmission | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Weight | About 6T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW*2 sets |

| Hydraulic system power | 7.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | Max 70m/min(customized) | Speed is adjustable according to customer’s request |

More pictures of the machine:

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP