Key Features Of Ultra-Dek-Trapezoidal Leg Standing Seam Roofing Machine May Include:

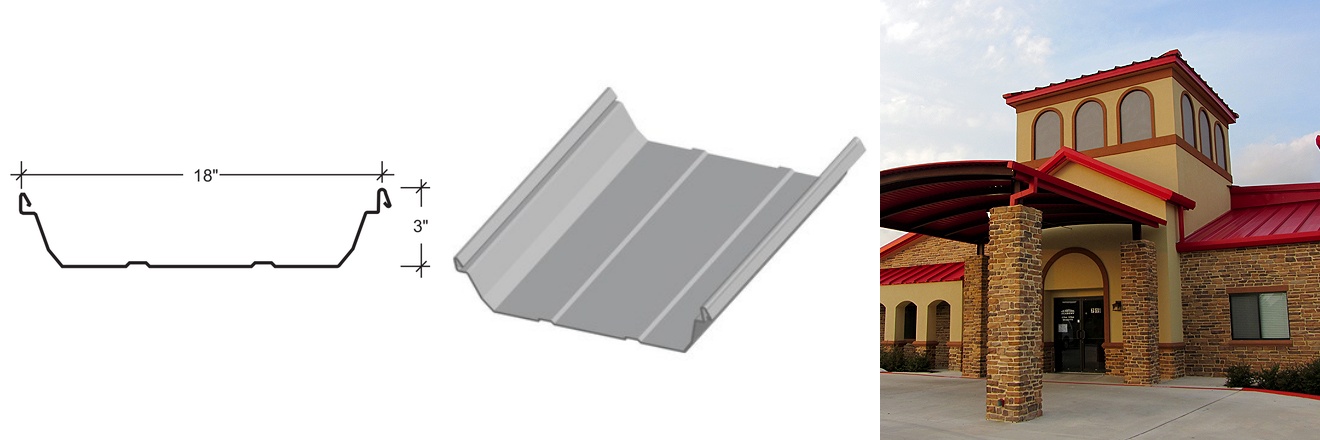

Dimensions: 24″ and 18″ wide by 3″ deep

Slope: 1/4:12

Panel Attachment: Concealed Fastening System; Low, High, Fix, Sliding

Gauges: 24 (standard); 22, 26 (optional)

Finishes: Smooth (standard); Embossed (optional)

Lengths: 55′ maximum is standard but longer lengths available by special request

- Power:5.5KW+3.0KW

- Size: 5.8m×1.2m×1.65m

- Weight:3 tons

- Materialof rollers: 45#CNC manufactures with

- chrome quenching

- Drive:Chain and gear

- Steps of rollers: 9rows

- Material of cutting blade:Cr12 1 Mov

- ElectricalStandard:220V/60HZ/3PH

- Forming Speed: 15m/min

- Control System: PLC (Omron)

- Uncoiler Capacity: 6 tons

Fasteners: The clips are available as sliding or fixed. two different clip heights are available to allow for thermal blocks.

Ultra-Dek-Trapezoidal Leg Standing Seam Roofing Machine

Ultra-Dek-Trapezoidal Leg Standing Seam Roofing Machine

The Ultra-Dek-Trapezoidal Leg Standing Seam Roofing Machine is expertly designed to manufacture high-quality, snap-together trapezoidal leg standing seam roof panels that excel in air leakage and water penetration resistance. Combining precision, efficiency, and durability, this machine empowers manufacturers to meet the growing demand for superior roofing solutions across industrial, commercial, and architectural projects.

Versatility and Precision

This state-of-the-art machine produces Ultra-Dek panels in 18-inch and 24-inch widths, making it suitable for various construction types and requirements. With a minimum slope of ¼:12, the panels are ideal for diverse applications and can be installed over open framing or solid substrates, such as metal decking, rigid board insulation, or wood decking. The machine supports multiple panel profiles, including Snap Seam and Mechanically Seamed designs, Ultra-Dek-Trapezoidal Leg Standing Seam Roofing Machine ensuring a fully weatherproof seal for long-term performance.

Efficient Production for Faster Turnaround

Streamline your manufacturing process with this advanced roll forming machine. It offers reduced lead times, especially for popular panel colors like Polar White, Snow White, Bone White, Slate Gray, Burnished Slate, Medium Bronze, and Colonial Red. These capabilities allow manufacturers to produce premium quality panels more quickly while maintaining MBCI’s renowned standards for durability and performance. Optional features, such as floating clip systems and UL90 or FM ratings, provide additional customization and reliability.

Durability and Cost-Effectiveness

Ultra-Dek panels, created using this roll forming machine, minimize fastener penetrations—a common source of leaks in traditional roofing systems—resulting in a virtually leak-proof solution. The machine’s ability to produce panels with various gauges, widths, and finishes allows manufacturers to cater to specific project needs. Weather-tight warranties further enhance customer confidence when project criteria are met.

Why Choose the Ultra-Dek Roll Forming Machine?

- High Efficiency: Designed for high-speed, precision manufacturing, ensuring consistent quality.

- Enhanced Versatility: Adaptable to a wide range of applications, substrates, and designs.

- Reliability: Long-lasting performance with reduced maintenance requirements.

- Customization: Supports diverse panel profiles, finishes, and optional features to meet unique project needs.

Upgrade your roofing production capabilities with the Ultra-Dek Roof Panel Roll Forming Machine, the perfect solution for creating durable, weather-tight, and aesthetically pleasing standing seam roof panels. Enhance efficiency, expand your offerings, and meet the demands of today’s competitive roofing market with this innovative machine.

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

1.5″ Form Deck Roll Forming Machine Profile: Standard Cover Width: 36″ Additional Cover Widths Available: […]

STAY IN THE LOOP