R-Panel metal roofs are the long-lasting and Beautiful stunning metal roofing option.They are easy to install and this course cuts down on labor,time,and disposal costs.These R panel roofs are available in many different colors.R-Panel/PBR-Panels are very popular for both local and commercial roofing systems.

R-Panel Metal Roof is built with 36-inch-wide interconnected metal panels.These metal roof types feature overlapping seams which limit water infiltration,but the exposed fasteners can be a point of weakness. Cangzhou Zhongtuo Cold roll forming machine company is one of the leading R panel metal machine manufacturers in the R-Panel metal roof,and specialized in the design,manufacture the roll forming machines,and PRB panel roll forming machine.

Differences between R-Panels and PBR-Panels

Rib type roll forming machine PBR”Panel stands or Purlin Bearing Rib Panel is far better to the “R”panel for most roof and siding wall applications.These PBR-Panels include a larger overlap section (purlin bearing leg)between panels that give the metal roofing sheets more strength. R-Panels PBR Panels design for commercial,industrial,and steel frame building applications. The primary difference between the R-Panel and PBR-Panel is the Purlin-Bearing Leg on the PBR-Panel.This leg provides better support for roof applications.

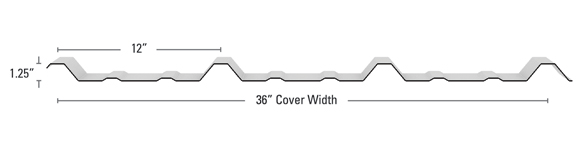

Profile drawing:

PBR panel roll forming machine forming machine, mainly component as belows:

- Hydraulic uncoiler

most customers choose 5 tons hydraulic decoiler, because hydraulic decoiler machine adopts hydraulic control core shaft expansion and shrinking, convenient, working fast and stable.

Driven control by electrical motor, high precision, good degree of automation, frequency converter control, the speed can be adjusted.

| Decoiler | Work type | Passive |

| Inner diameter | 450-550 mm | |

| Loading capacity | 5 tons | |

| Max coil width | 1450 mm |

- Feed device

Responsible for feeding metal coil into the forming machine

One set guiding roller, Steel plate welded platform to carry the sheet and feed into roll

forming system; Feeding width is adjustable with the handle wheels

- Main roll forming machine:

According to the design specifications of the roof panels, the molding mold will have different shapes and sizes, also different rollers station.

Rollers material normally use 45# steel and GCR15 steel, quenched.

| Roll forming machine | Feeding device | the platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet. |

| Rolling shaft | Shaft Material: 45# STEEL | |

| Shaft diameter: 80 mm | ||

| Tampering treatment, prevent deformed and improve the hardness | ||

| Roller | Roller material: 45# steel | |

| Chromed treatment (Cr thickness:0.05 mm), anti-corrosion,Increase hardness, ensure the precision and good abrasion performance | ||

| Rolling station | 18 stations | |

| Work speed | 0-15 m/min | |

| Machine structure | Middle plate welded structure | |

| Machine basic frame | Hot rolled H-beam | |

| After the whole welding, vibration is used to weld the stress. After large-scale planer machining, the horizontality and rigidity of the frame are ensured. | ||

| Bearing | Chinese famous brand Harbin | |

| Work power | 5.5 kw | |

| Transmission | By Chains |

- Cutting device

After the R panel roll forming machine is formed, the cutting device cuts it to the specified length.

| Cutting system | Work type | Hydraulic cutting |

| Driving method | By pillar type Cylinder, | |

| Hydraulic motor power | 5.5 kw | |

| Cutter material | GB-Cr12 | |

| Cutting length tolerance | ±10 m/2mm | |

| Oil pump | Solenoid valves:1 set | |

| Cutting feature | Steady and safe working condition and low sounds | |

| Oil tube and wires connection | All the tubes and wires will be marked by the numbers or letters,So that it will be very easy to connect for the new. |

- Control system:

used to control the entire molding process to ensure the accuracy and quality of the product. Control system can choose Delta or Siemens brand, international famous brand, it is more easy to replace once some parts damage after some years.

| Control system | Frequency brand | Delta |

| PLC brand | Delta | |

| Screen type | Touch screen & buttons | |

| Screen language | English/Chinese/as request | |

| Low pressure electrical part | Schneider | |

| Counter brand | Omron | |

| Function | Cutting length control, cutting quantity control, and speed control |

The ZTRFM NLT350 digital intelligent purlin machine represents a new era of digital manufacturing. It […]

Light Gauge Steel Framing Machine Specification Width(web): 89mm Height(flange): 41mm Lip:7-12mm The machine match with 3 sets […]

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

STAY IN THE LOOP