Description of Resilient Furring Channel Rolling Forming Machine

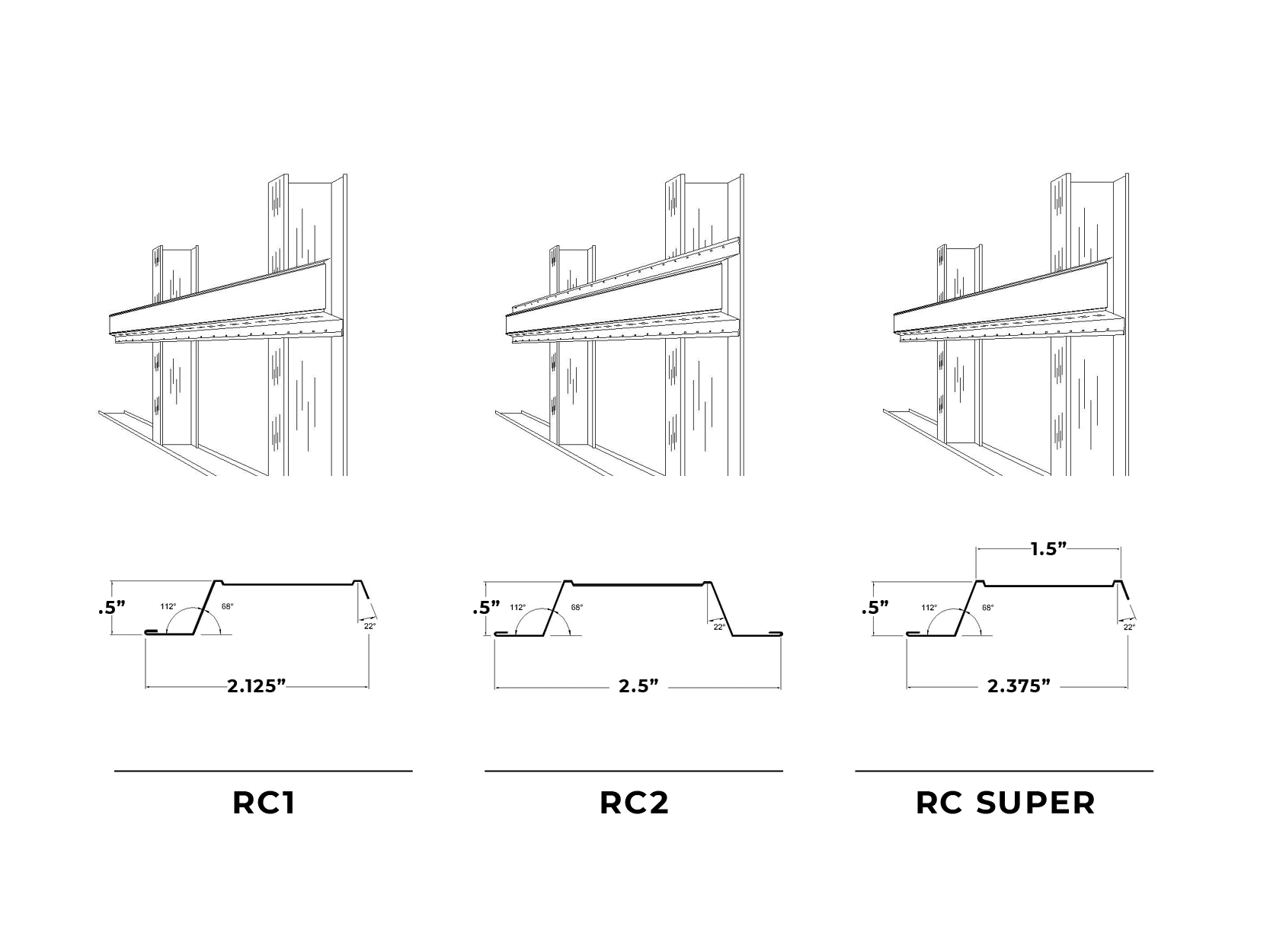

Resilient channels provide a ½” gap between gypsum board and the wall studs or ceiling joists, improving sound isolation and boosting the STC (Sound Transmission Class) ratings in wall and floor-ceiling assemblies. The RC1 and RC2 models feature 1 ¼” flanges for attachment, while the RC Super version comes with a larger 1 ½” flange.

RC Super Single Leg Resilient Channel

The RC Super channel from Super Stud is designed to improve the STC rating of both wood and metal framing systems. It acts as a cross-furring component and must be installed perpendicularly to the framing. It comes with pre-punched holes spaced 2” apart to simplify attachment, and screws should be used for installation, as nails are not recommended.

RC-1 Single Leg Resilient Channel

The Super Stud RC-1 also enhances the acoustical performance of your framing by increasing the STC rating. Like the RC Super, it is installed perpendicular to the framing members and features pre-punched holes spaced 2” on center. Installation should be done using screws, avoiding the use of nails.

RC-2 Double Leg Resilient Channel

Typically used in ceiling applications where multiple layers of gypsum board are involved, the Super Stud RC-2 channel enhances STC performance for both wood and metal framing. It is mounted perpendicular to framing members and comes with pre-punched holes every 2” for ease of installation. Screws are recommended for attachment to framing, as nailing is not advised.

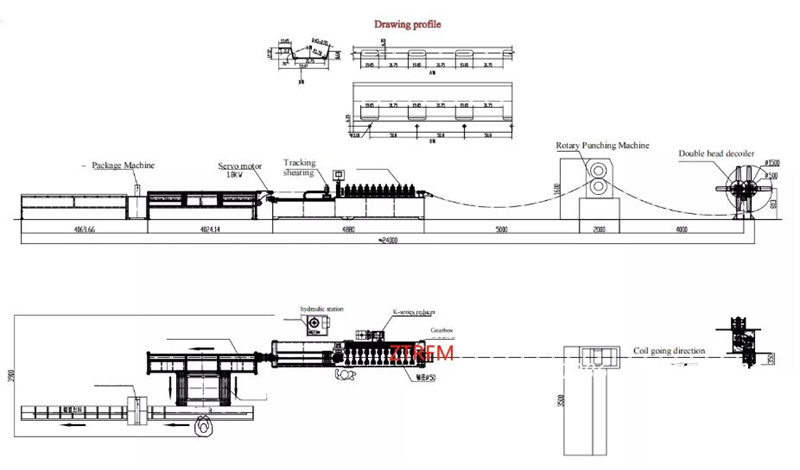

(1/2”HEIGHT)Resilient Channel Roll Forming Machine Specification ll

- The highest speed it can reach 70m/min including the punching process.

- Design with double head decoiler for changing coil easily and supporting working in a high speed.

- Use the rotary punching instead of normal CNC punching, small noise but higher speed.

- 16 roller station rolling forming machine with servo tracking system.

- With the package machine for fast package.

- Whole line is fully automatic, normally speaking one worker can make the work easily.

- PLC operation.

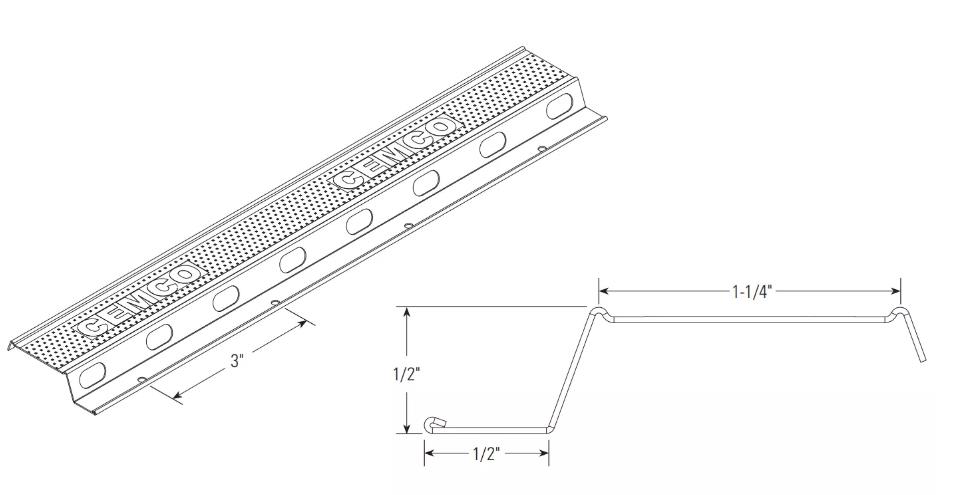

Profile drawing:

These resilient channels are constructed with a 1-1/4” upper flange and a 1/2” flange for nail or screw attachment, providing a 1/2” furring depth from the face of the wall stud.

(1/2″ HEIGHT)Resilient Channel rolling forming machine working flow:

The Technical Specifications Of The Resilient Furring Channel Rolling Forming Machine:

| (1/2″ HEIGHT)Resilient Channel rolling forming machine | ||

| 1.Formed Material | GI | Thickness: 0.3-1.0mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 14 rows(As your requirement) |

| Diameter of shaft | 50mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | Gearbox transmission | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Weight | About 3T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW |

| Hydraulic system power | 5.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 70m/min(customized) | Speed is adjustable according to customer’s request |

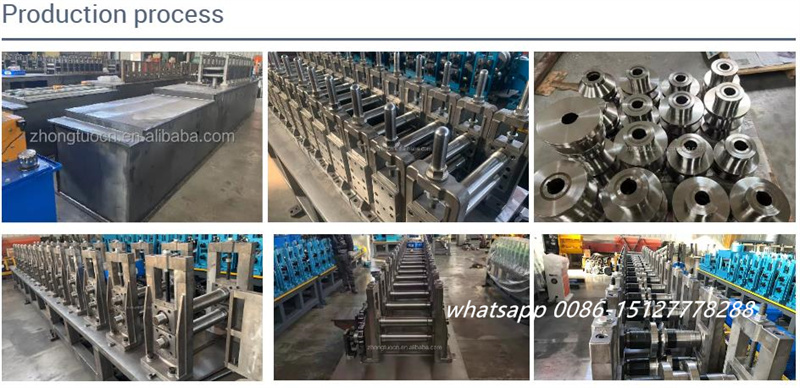

More pictures of the machine:

Technical Specifications 2025 Fully Automatic Container Side Wall Panel Roll Forming Machine This production line is

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability This advanced roll forming

LED Light Box Profile Roll Forming Machine The Component Specifications of this roll forming system

1100 Series High-Speed Automated Roll Forming Line Integrated Production Line Configuration Manual Decoiler → Roll Forming Unit → PLC

STAY IN THE LOOP