Description Of Australia Trimdek Sheet Roll Forming Machine

The Trimdek sheet roll forming machines are manufactured in China and meet Australian safety standards. The Trimdek roofing profile features a long-span design, which allows for wider support spacing, offering a versatile, lightweight, and durable solution for cladding applications.

With a coverage width of 760mm, Trimdek is both cost-effective and quick to install. Its 28mm rib height, combined with a specially engineered capillary groove, ensures excellent watertight performance, even on roofs with as little as a two-degree pitch.

Sheet Coverage Details:

– Cover width: 762mm

– Actual sheet width: 820mm

– The standard thickness for Steel sheets ranges from 0.42 to 0.48 BMT

In Australia, popular roofing profiles include corrugated sheets, Kliplok 700, and Spandek. To improve the durability of roofing products, Australian manufacturers typically use high-strength materials with a yield strength of 500 MPa. However, these stronger materials can be more brittle, which increases the risk of breakage during the roll forming process.

ZTRFM Machinery Factory has extensive expertise in designing and manufacturing roll forming machines, including those for gutters, fascia, and C purlins, specifically tailored to meet the needs of the Australian market. We specialize in creating customized roofing machines designed to match your unique roofing profile or design specifications.

Profile Drawing:

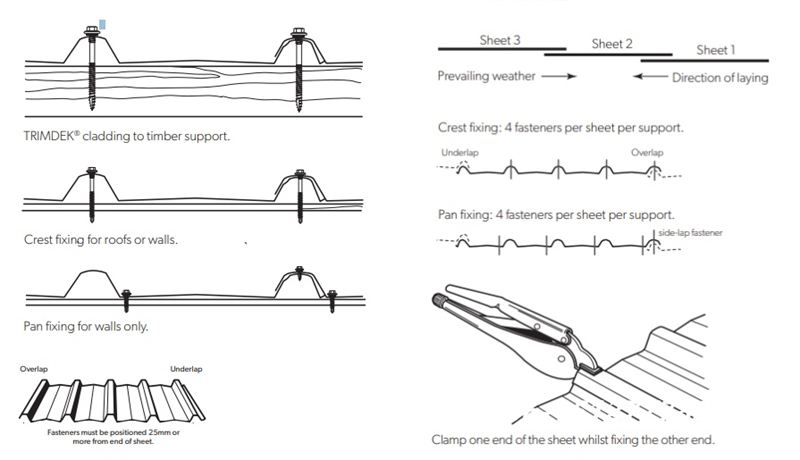

Typical Applications:

Typical Applications:

TRIMDEK Roof Sheets and Walling – Durable and Energy-Efficient

TRIMDEK ZTRFM steel roofing and cladding is a secure, durable, and energy-efficient choice for both residential and commercial projects. Designed to withstand Australia’s tough climate, TRIMDEK offers long-lasting performance and modern style.

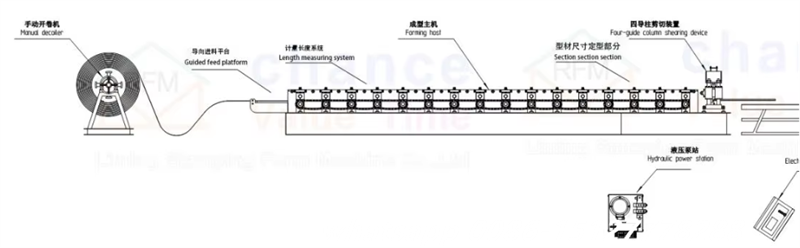

Working Flow chart:

Steel coil uncoiling → steel plate feeding → shape forming → size setting → hydraulic cutting-finished product splicing

The Technical Specifications Of the Australia Trimdek Sheet Roll Forming Machine :

|

Australia Trimdek Sheet Roll Forming Machine |

|||

| Series | Details | Parameter | Comment |

| Material | Raw material | Galvanized steel | Customer confirmed |

| Material thickness | 0.3-0.7mm | ||

| Decoiler | Roller station | 20-22 station | The standard one to match the production line |

| According to customer’s requirement | |||

| Loading capacity | 7.5 Tons | ||

| Coil inner diameter | 450-600 mm | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 45# steel with tempering treatment | ||

| Shaft diameter | 75 mm | ||

| Roller material | GCr12MoV | ||

| Rolling station | 18 stations | ||

| Work speed | 15-20 m/min (without punching holes) 0-20m/min (with holes) | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Steel plate welded | ||

| Bearing | Chinese famous brand Harbin | Famous brand of Harbin | |

| Work power | 7.5 kw+3kw | ||

| Transmission | Gear box transmission | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new!

|

|

| Decoiler, we can change to hydraulic one if you need. | |||

More pictures of the machine:

Light Gauge Steel Framing Machine Specification Width(web): 89mm Height(flange): 41mm Lip:7-12mm The machine match with 3 sets […]

Technological process Coil car—–uncoiling—straightening —-shearing machine—–stacking and piling system Brief introduction of the line ZT-12X1500 cut […]

Mar. 13th 2025 Cangzhou Zhongtuo’s Aluminum Drip Edge Flashing Roll Former Revolutionizes Production for American […]

Key Features Of Trapezoidal Standing Seam Roofing Machine Include: 1.0″ Mechanical Seam Panel seam: 1” […]

STAY IN THE LOOP